Automated Sampling collects samples directly from the grain flow with precision and repeatability, ensuring greater control and reliability in the process. Designed to operate continuously and safely, it adapts to different points along the line and meets modern industrial requirements.

The York Suspended Big Bag Scale performs automatic big bag loading with absolute precision, dosing exactly the programmed amount and eliminating manual errors. Easy to operate and fully integrated, it ensures reliability when filling large volumes.

The Belt Scale performs continuous weighing with high accuracy even in locations with limited vertical space, ensuring full control during grain loading and unloading. Integrated, automatic, and robust, it provides stable measurements in shipping and receiving lines.

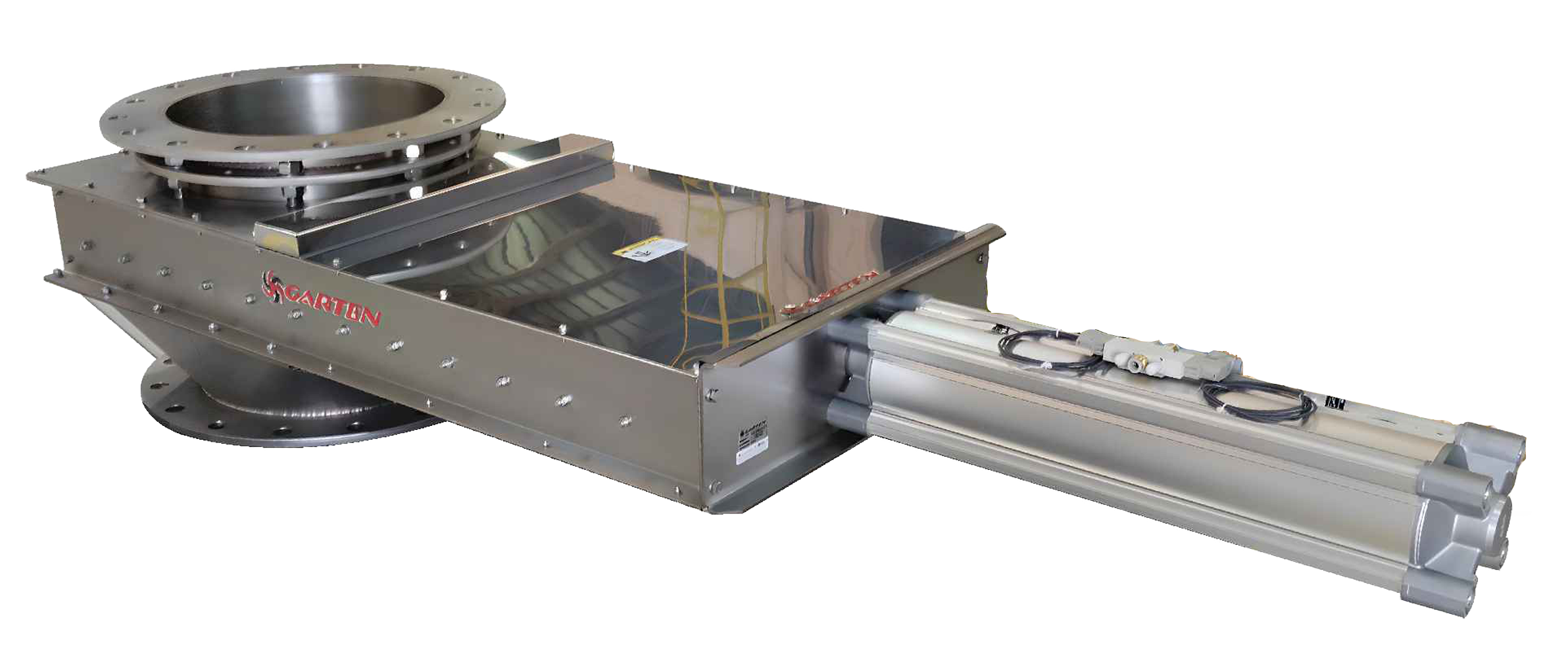

The Flow Scale delivers continuous weighing with extreme process precision, controlling industrial flow without interruptions and ensuring total stability, hygiene, and advanced automation. With integrated web connectivity and high-level communication capabilities, it elevates production control to a new level of efficiency.

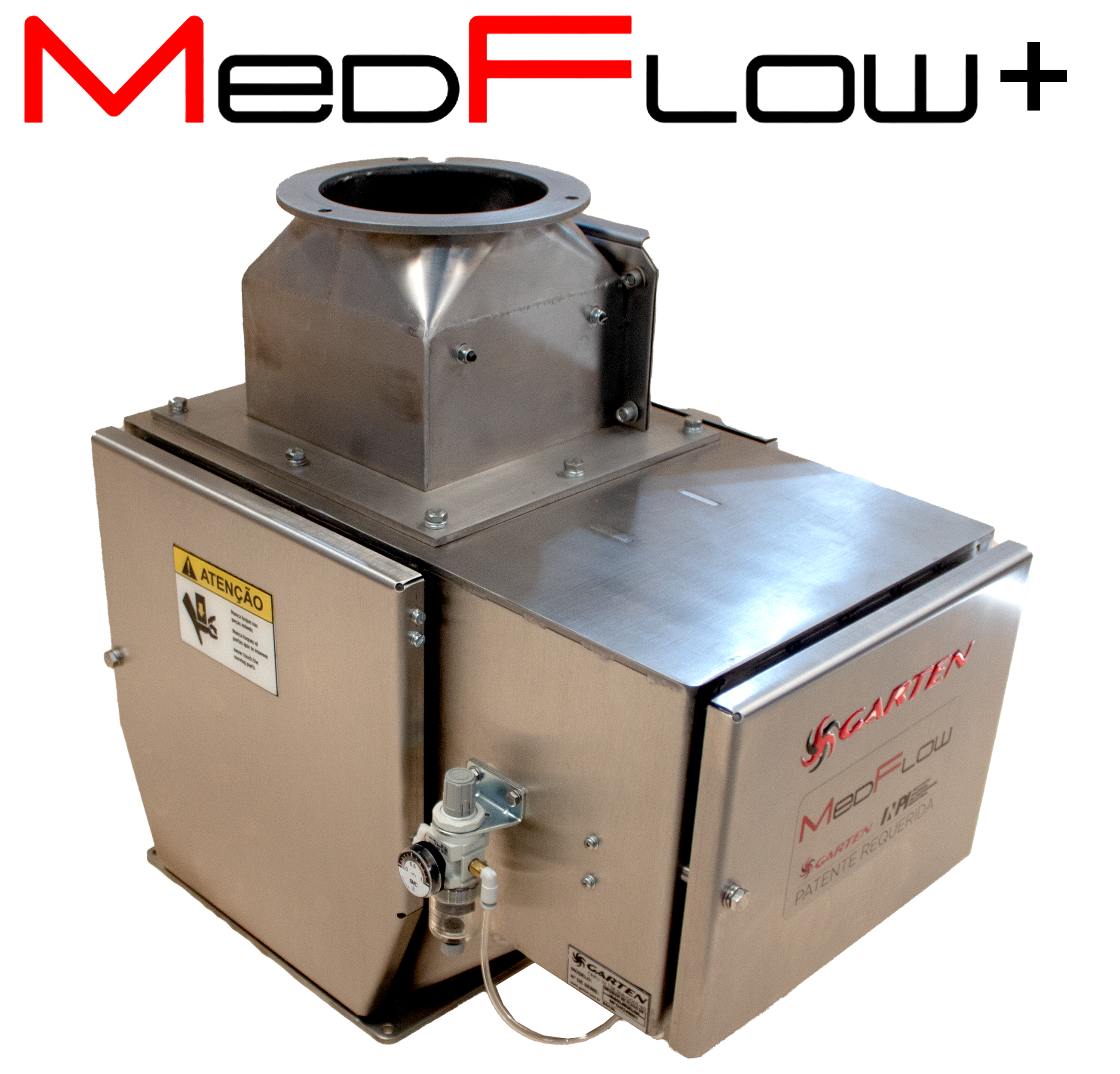

The MedFlow+ Flow Scale performs precise weighing of granular product flow directly at each point of the line, ensuring fine control, high repeatability, and quick adjustments during processing. Compact, hygienic, and fully integrated with automation.

The Missouri Expedition Scale automates the weighing and loading of grains with precision, ensuring exact dosing, speed, and total reliability in every cycle. With data logging, connectivity, and system integration, it enhances control and efficiency in expedition operations.

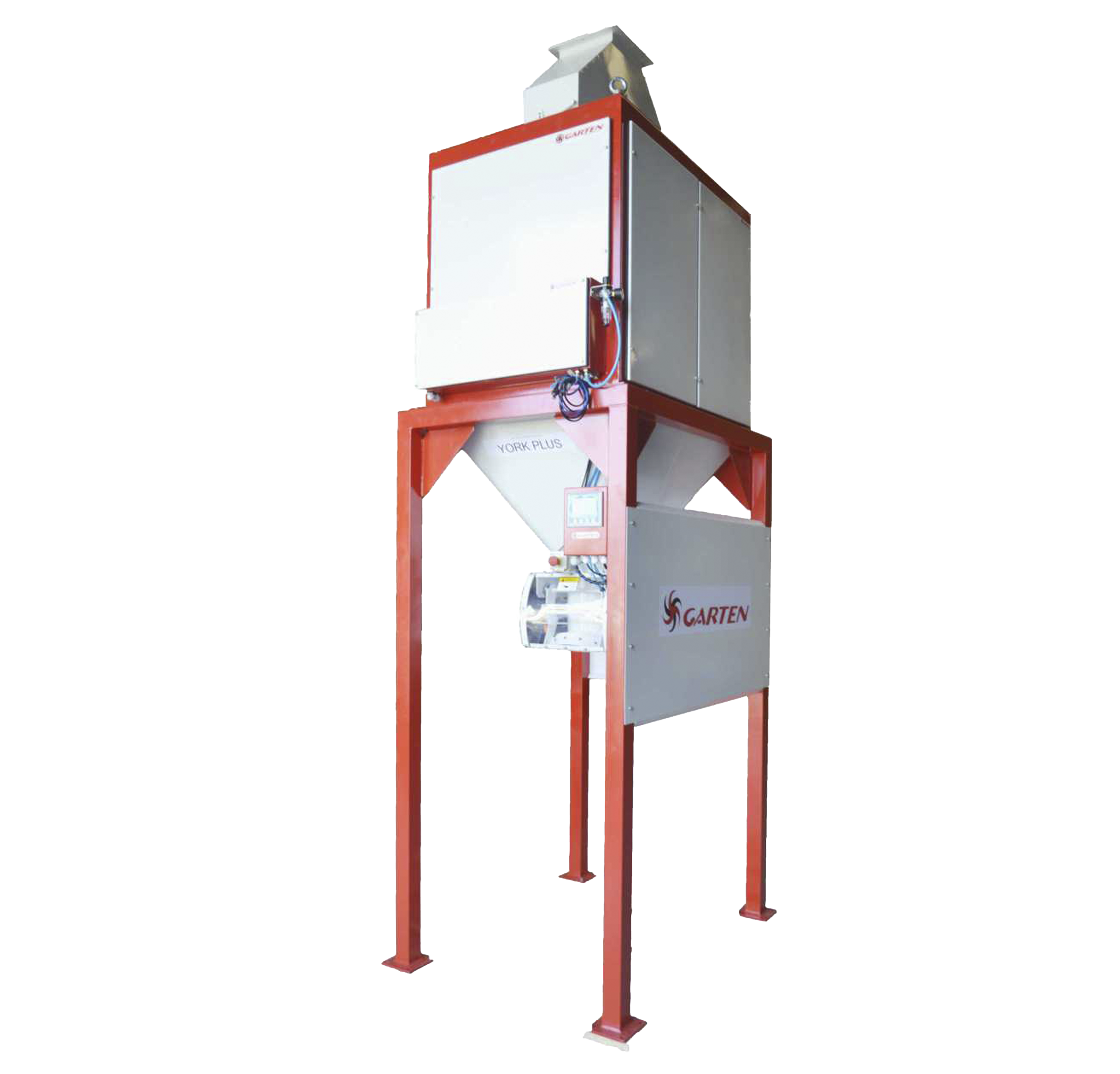

The York Plus Dual-Bagging Scale maximizes productivity by operating two independent compartments in sync, ensuring high bagging accuracy and continuous, interruption-free flow. Fast, robust, and fully integrated, it delivers superior performance in industrial bagging lines.

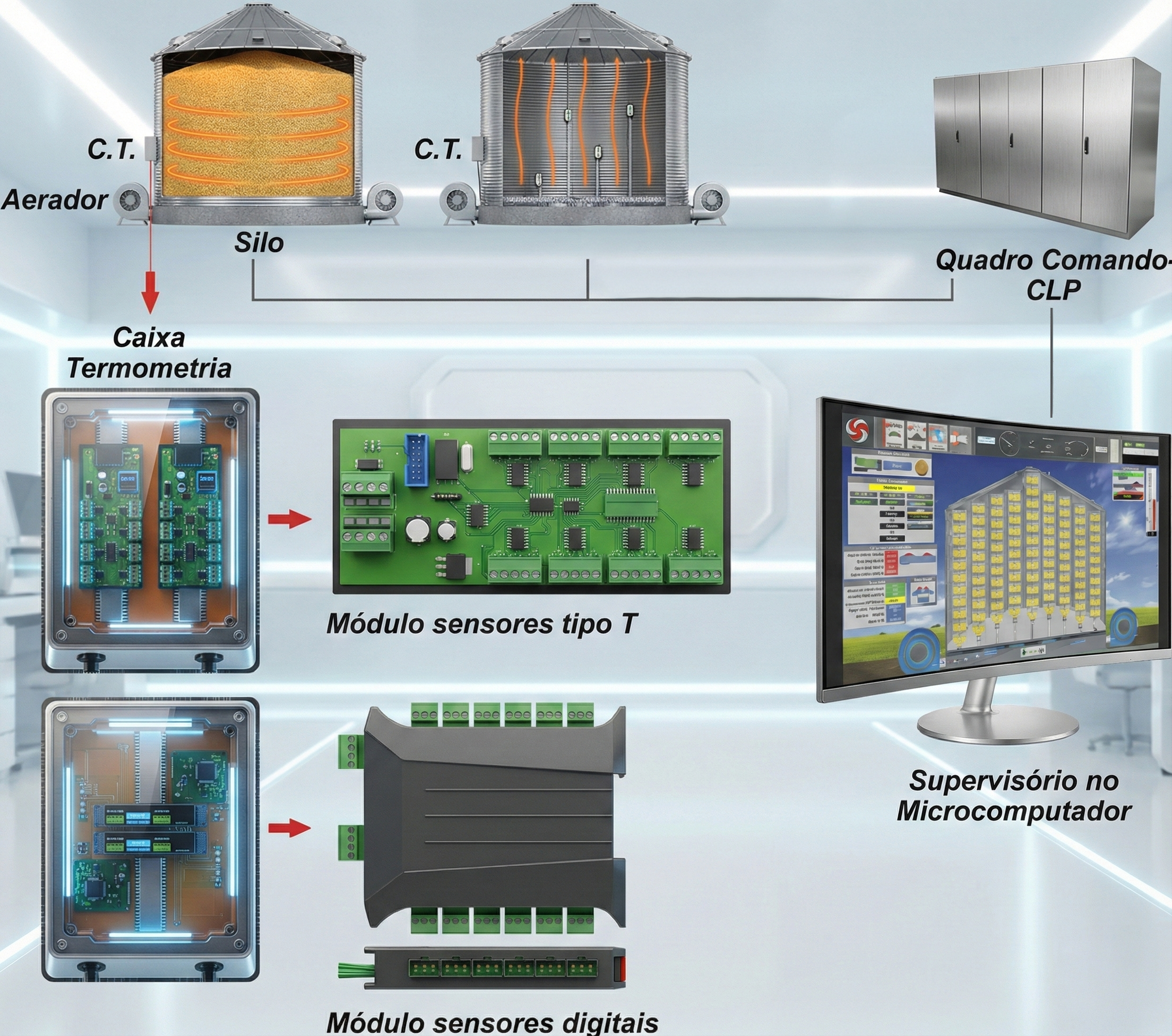

The switching units organize the sequential reading of temperatures in silos, ensuring continuous thermal monitoring, real-time analysis, and the prevention of conditions that affect the quality of stored grains.

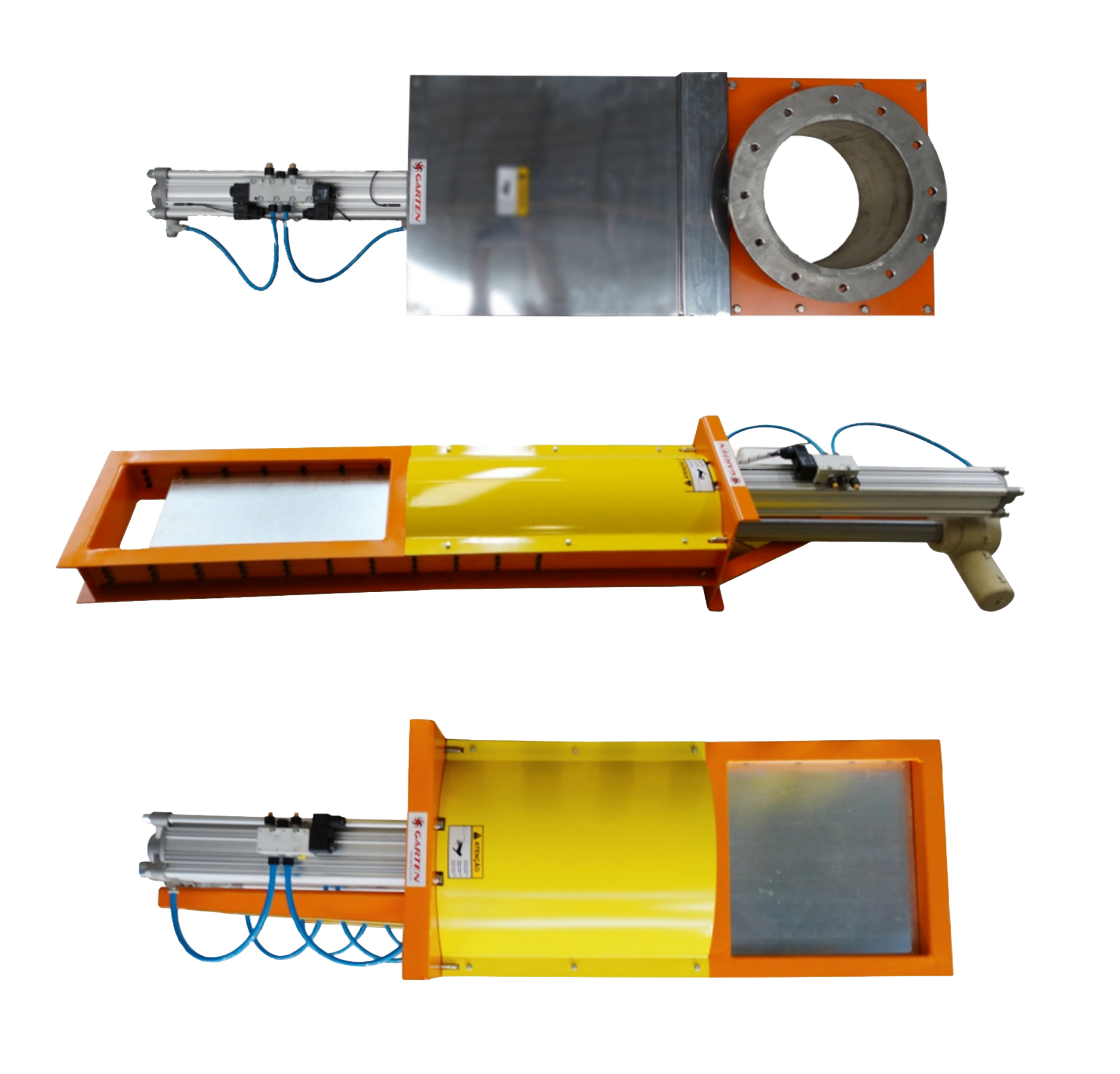

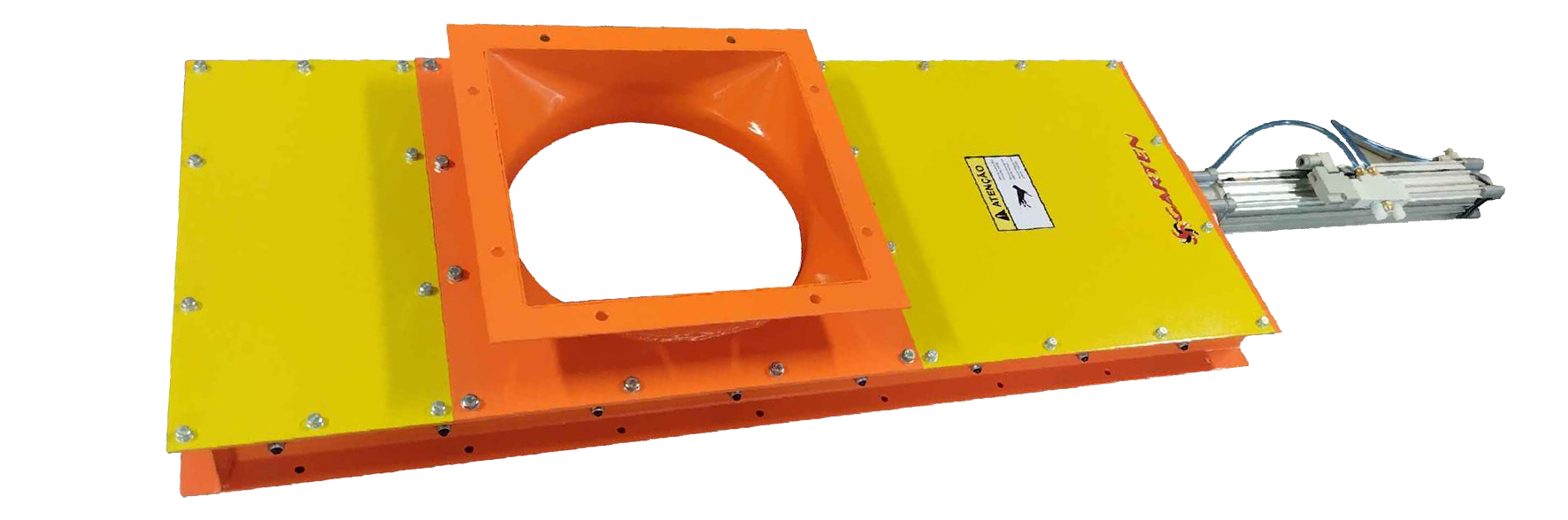

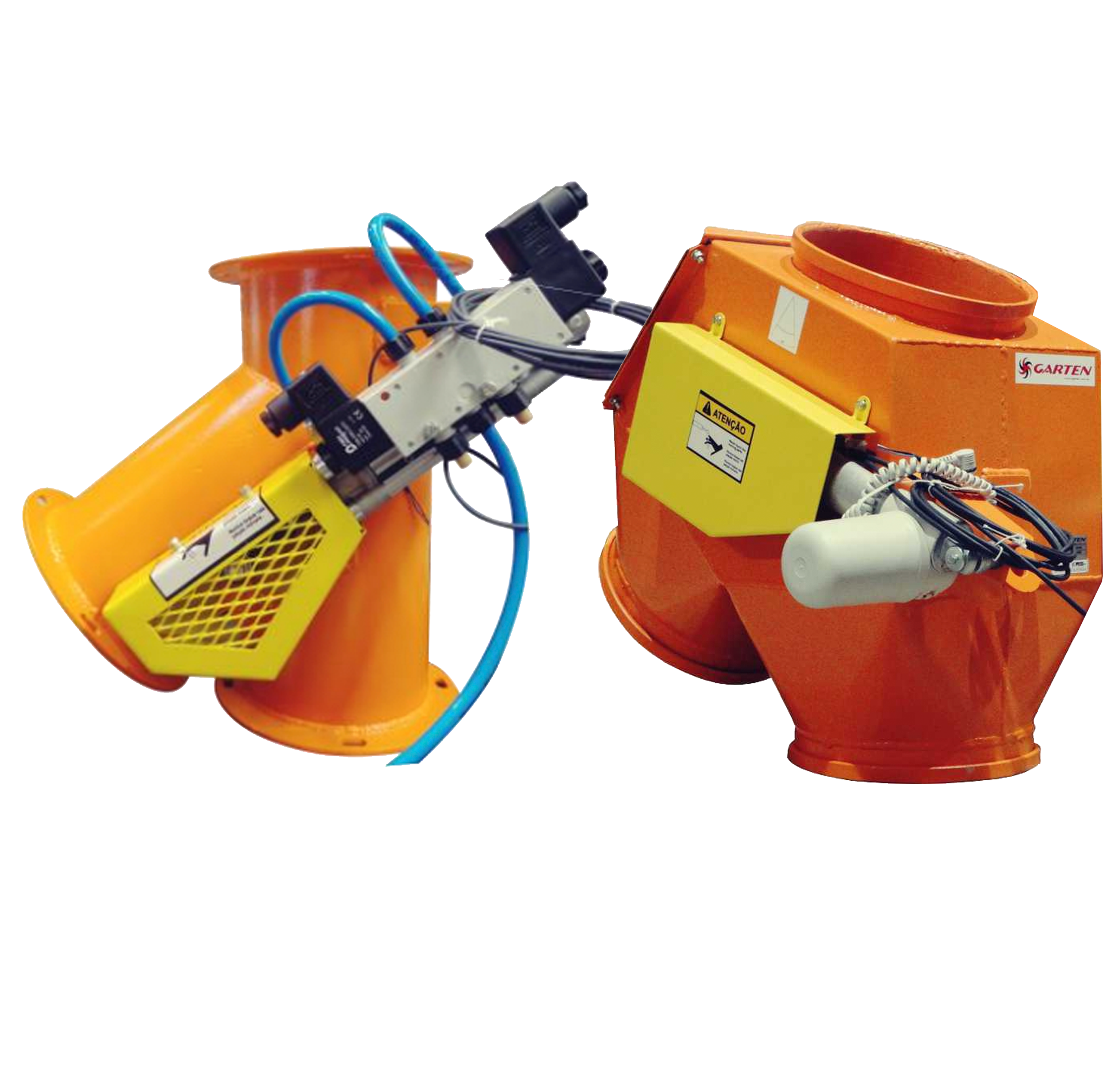

The gate ensures flawless control of grain flow, operating with speed, safety, and total reliability even in demanding industrial lines. With automatic pneumatic actuation, a self-cleaning design, and direct integration into automation, it guarantees continuous operation without blockages.

The Grain Fumigation Gate ensures highly efficient fumigation with airtight sealing, precise gas control, and automatic operation, reducing costs and protecting grain quality. With advanced engineering, it delivers safety and performance in fumigation and flow-control operations.

The Pneumatic Gate for Parboiling Tank optimizes the discharge of soaked rice with continuous flow, secure sealing, and automated operation, maintaining hygiene and efficiency in the most critical stage of the parboiling process.

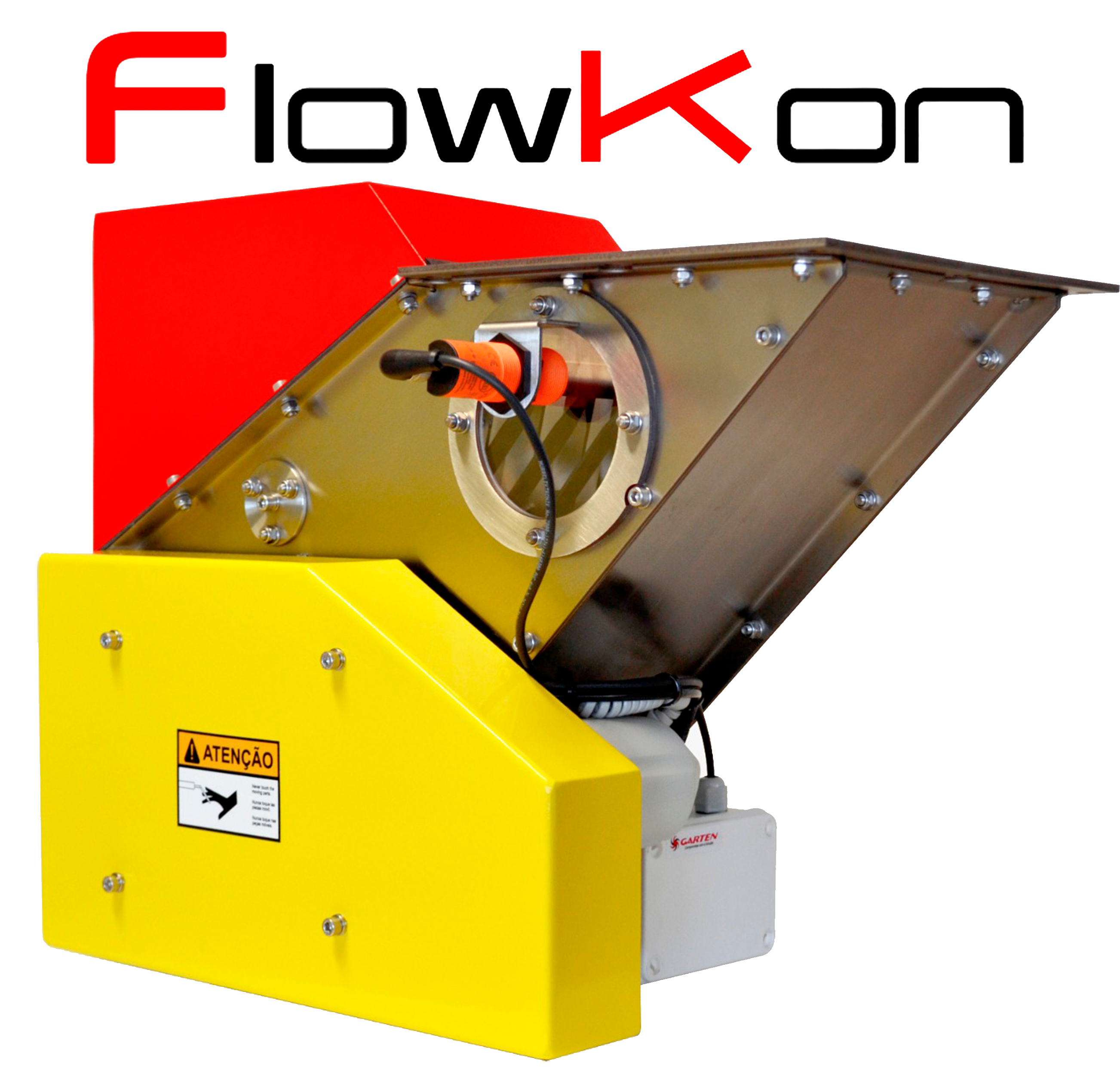

The FlowKon precisely controls the feeding of granular products, ensuring consistent dosing and stability in food production lines. Compact and easy to integrate, it optimizes flow, increases efficiency, and ensures process quality.

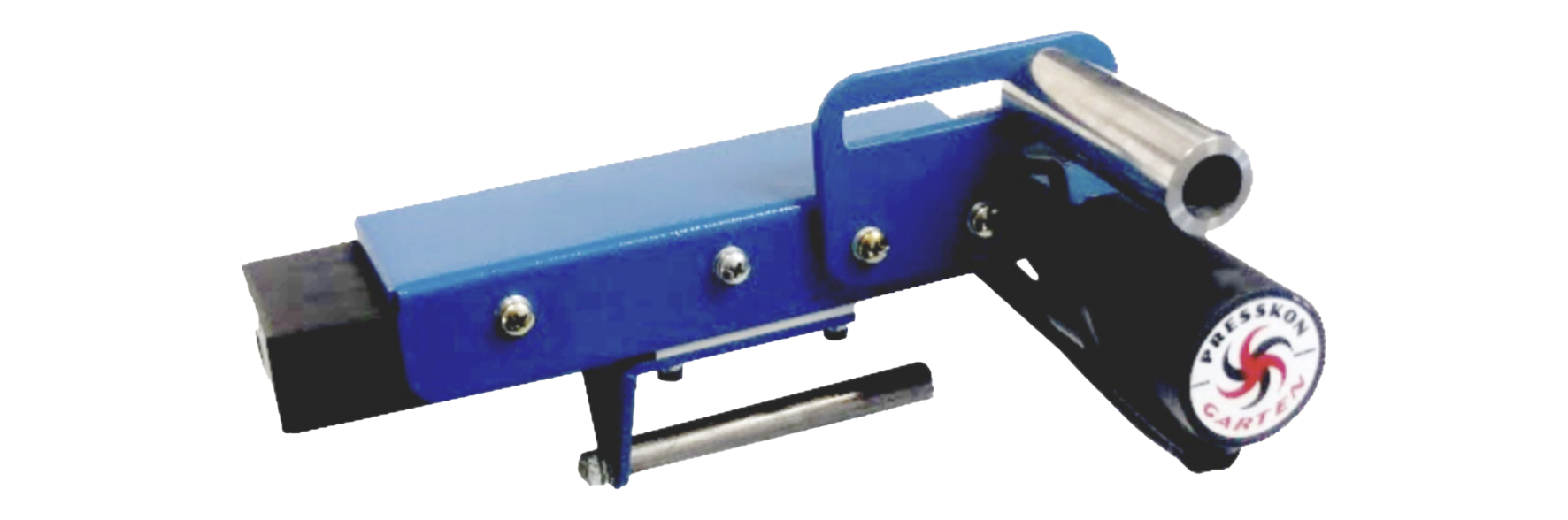

The PressKon automates pressure control in polishers and whiteners, adjusting the rice flow in real time to ensure consistent whitening and polishing. With motorized actuation and HMI supervision, it provides operational precision and full integration with the plant’s automation system.

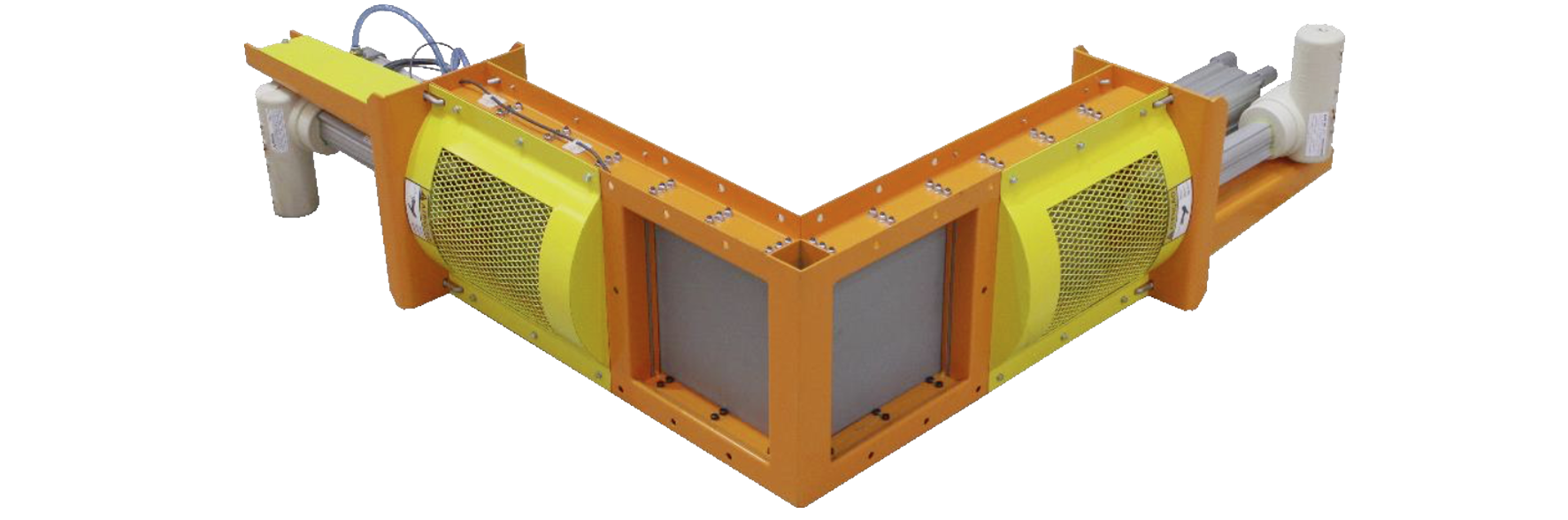

The Flow Diverter keeps grain processing in constant motion, redirecting the product with precision and eliminating buildup that could interrupt the line. With electric or pneumatic options, it ensures efficiency, stability, and full adaptation to the plant’s infrastructure.

The Flow Divider ensures precise division and modulation of grain flow in special applications, maintaining continuous operation without buildup and with total stability. With pneumatic and electric actuation options, it provides fine control and direct integration with industrial automation.

The Berlin gravimetric doser performs proportional mixing of granular products with extreme precision, ensuring weight-based dosing even with density variations. Compact and fully integrated, it controls multiple dosers simultaneously and ensures exact proportions in continuous processes.

The Volumetric Doser accurately measures the volume of grains in continuous flow, ensuring uniform loads and eliminating failures caused by weight variations. Robust, automatic, and integrated into automation systems, it ensures exact volumes in processes that demand repeatability.

InfoKlima provides precise and continuous environmental monitoring, measuring temperature, humidity, and rainfall. Compact, robust, and efficient, it ensures reliable readings in any environment and direct integration with automation systems.

The Diff Press Differential Pressure Meter monitors the pressure difference between two environments in real time and sends this data directly to the automation system, ensuring precise and immediate control.

The Med-Umi measures grain moisture directly in the dryer flow, delivering laboratory-level precision in real time, with efficient and fully controlled operation. With cutting-edge technology and full integration, it ensures superior quality and eliminates uncertainties in the process.

The MedFlow measures the flow of granular products with high precision and controls the amount entering the process, ensuring stable feeding and fine adjustments in the machines. With simple and fast installation, it optimizes production, reduces losses, and brings real control to the line.

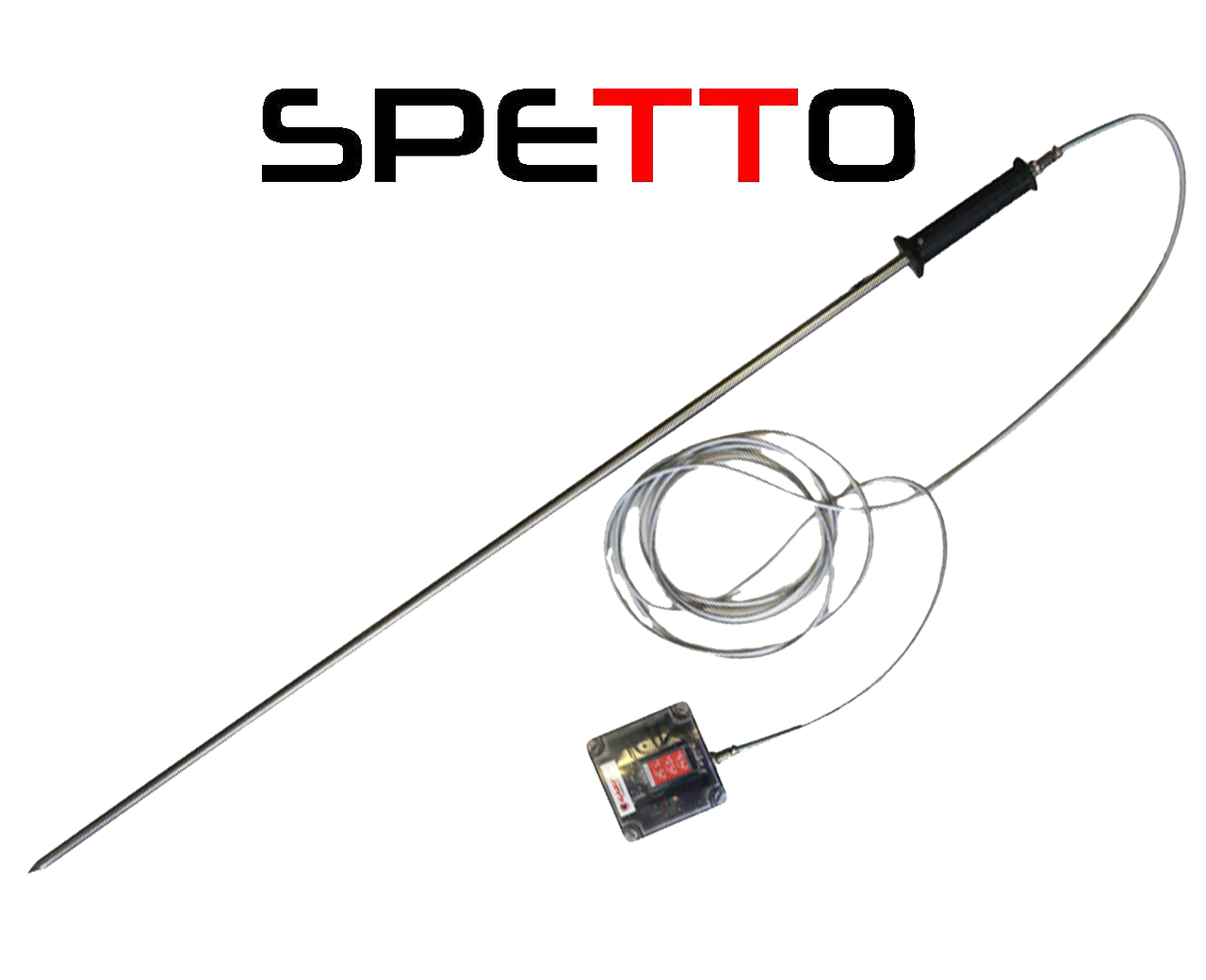

The Spetto accurately measures temperature at depth in germination tanks, revealing the true thermal condition across all grain layers. Portable and simple to use, it ensures reliable control of the malting process and quick decisions based on real data.

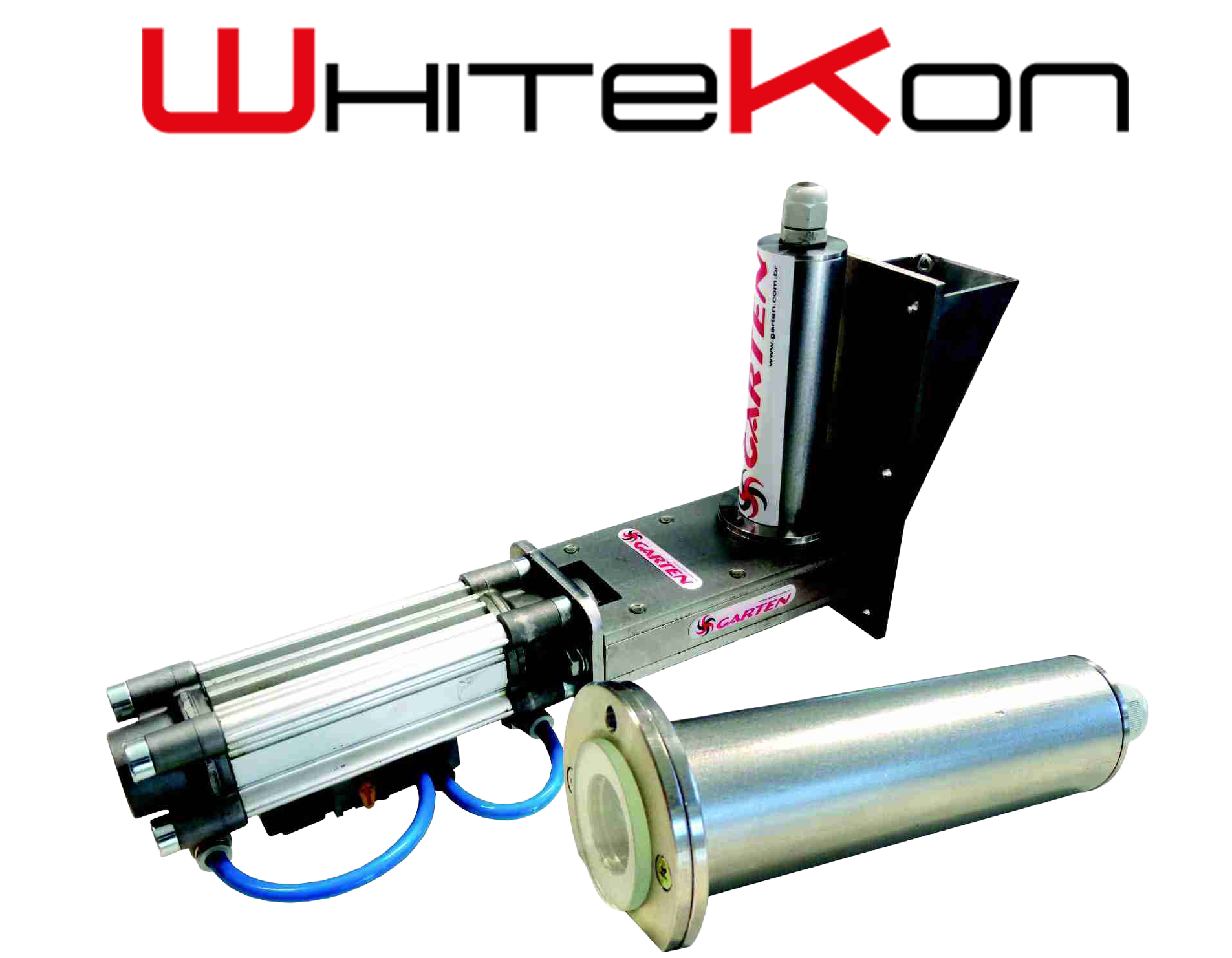

The WhiteKon measures whiteness levels directly at the outlet of polishers and whiteners, ensuring precision and automatic machine adjustment in real time. With an RGB sensor and microprocessed control, it delivers consistent results and full integration with industrial systems.

The WhitePRO is a portable whiteness meter, allowing practical use at any point in the plant, with precise measurements, simple operation, and autonomy that supports continuous process control.

The Sheriff monitors critical conveyor points in real time, identifying failures before they become stoppages, accidents, or equipment damage. With strategic sensors and industrial communication, it provides continuous and reliable protection for the entire line.

The TempKon monitors, in real time, the temperature of the grain mass at the outlet of polishers and whiteners, ensuring precise thermal control at critical processing points.

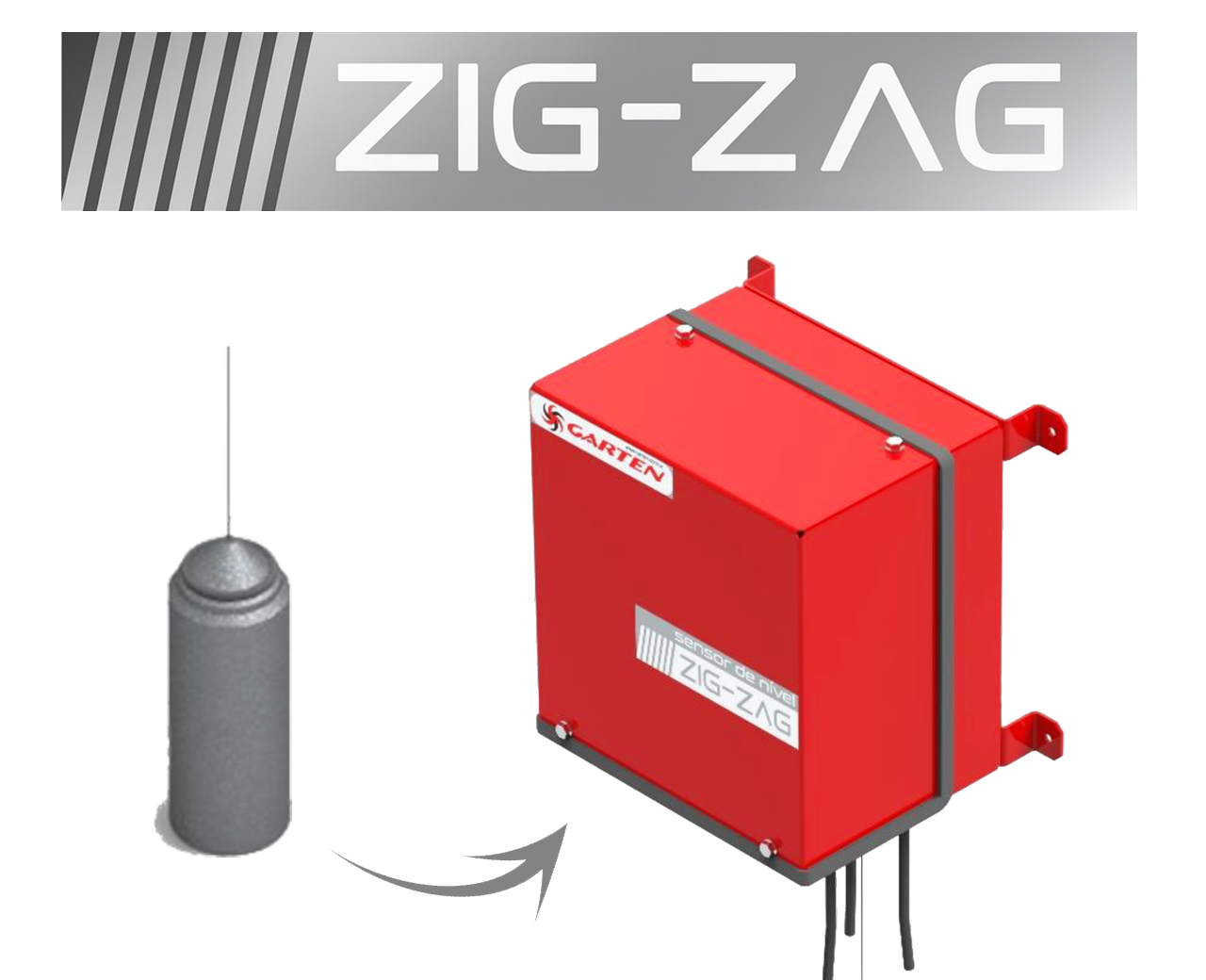

The ZIG-ZAG accurately measures product height in silos and bins, supplying the automation system with the approximate stored volume. With a programmable pendulum and armored construction, it ensures reliable readings even in dusty environments.

The GasMeter detects, with extreme advance notice, any abnormal increase in the cellular respiration of grains in the silo, alerting even weeks before a temperature rise occurs. With full integration into the STARK system, it ensures improved preservation and reduces storage losses.

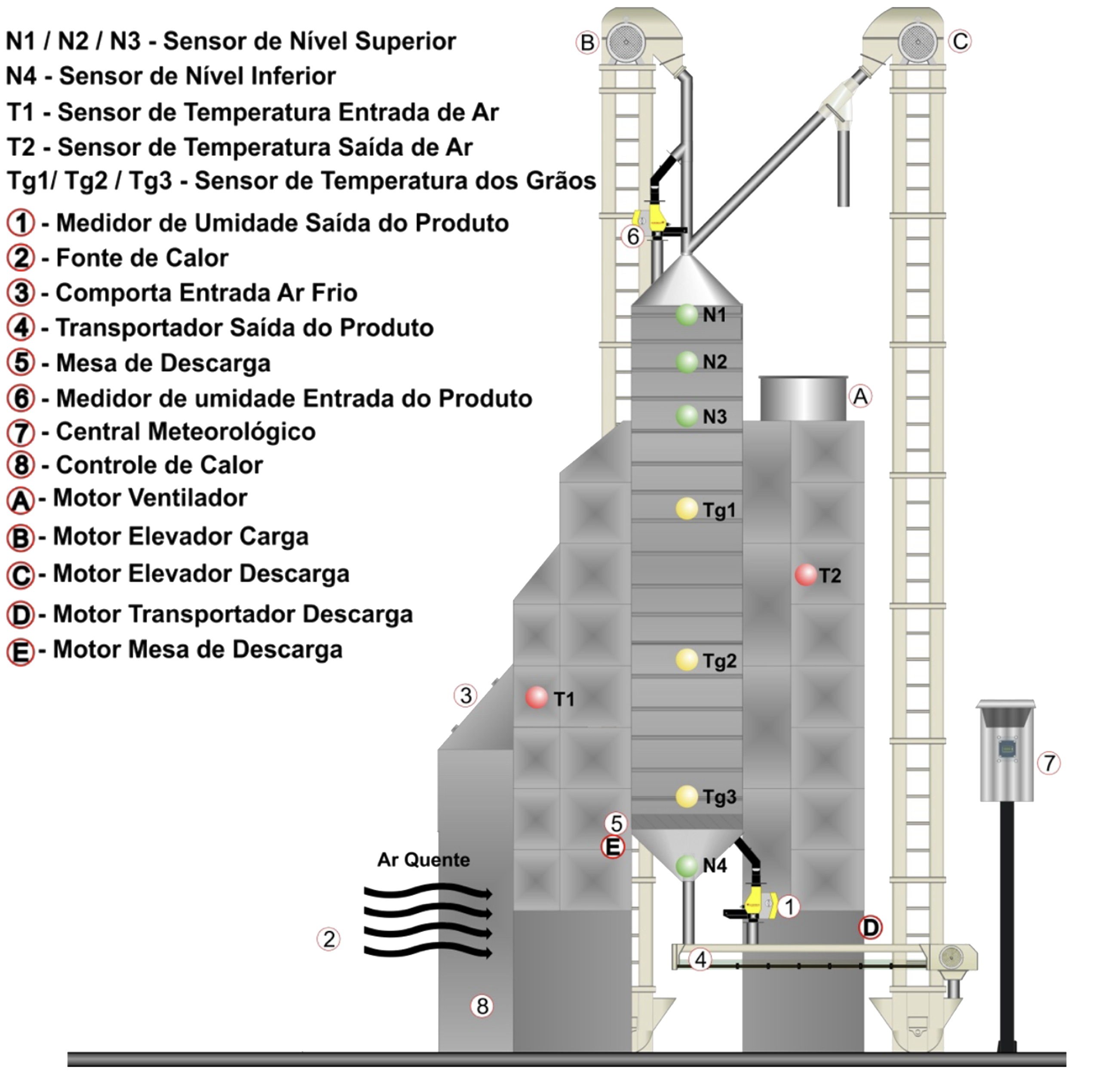

The Dryer Control System automates the entire drying process, monitoring moisture, temperature, and grain flow to ensure continuous, efficient, and fully stable operation. With comprehensive supervision and industrial integration, it ensures superior final quality and maximum process safety.

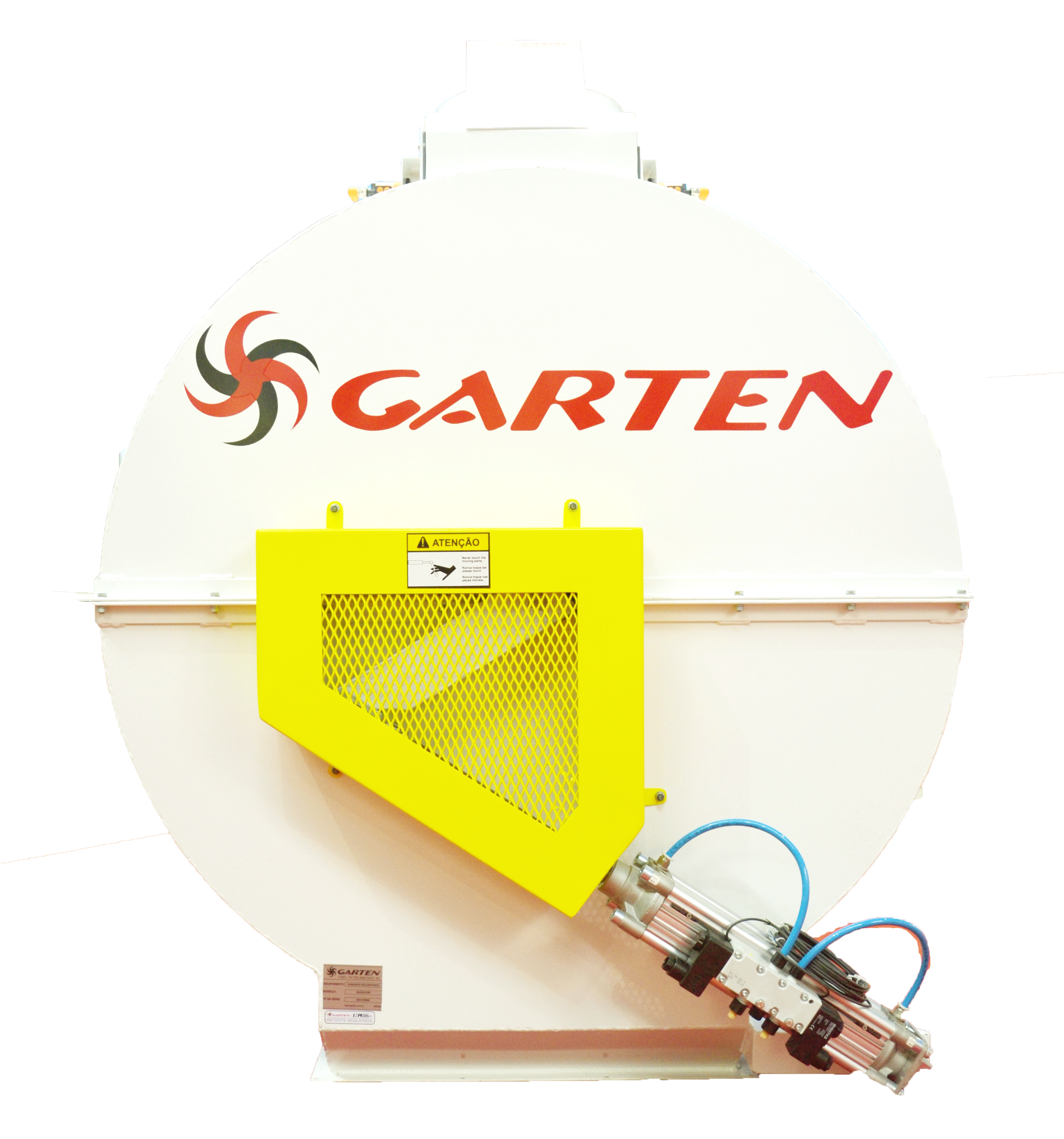

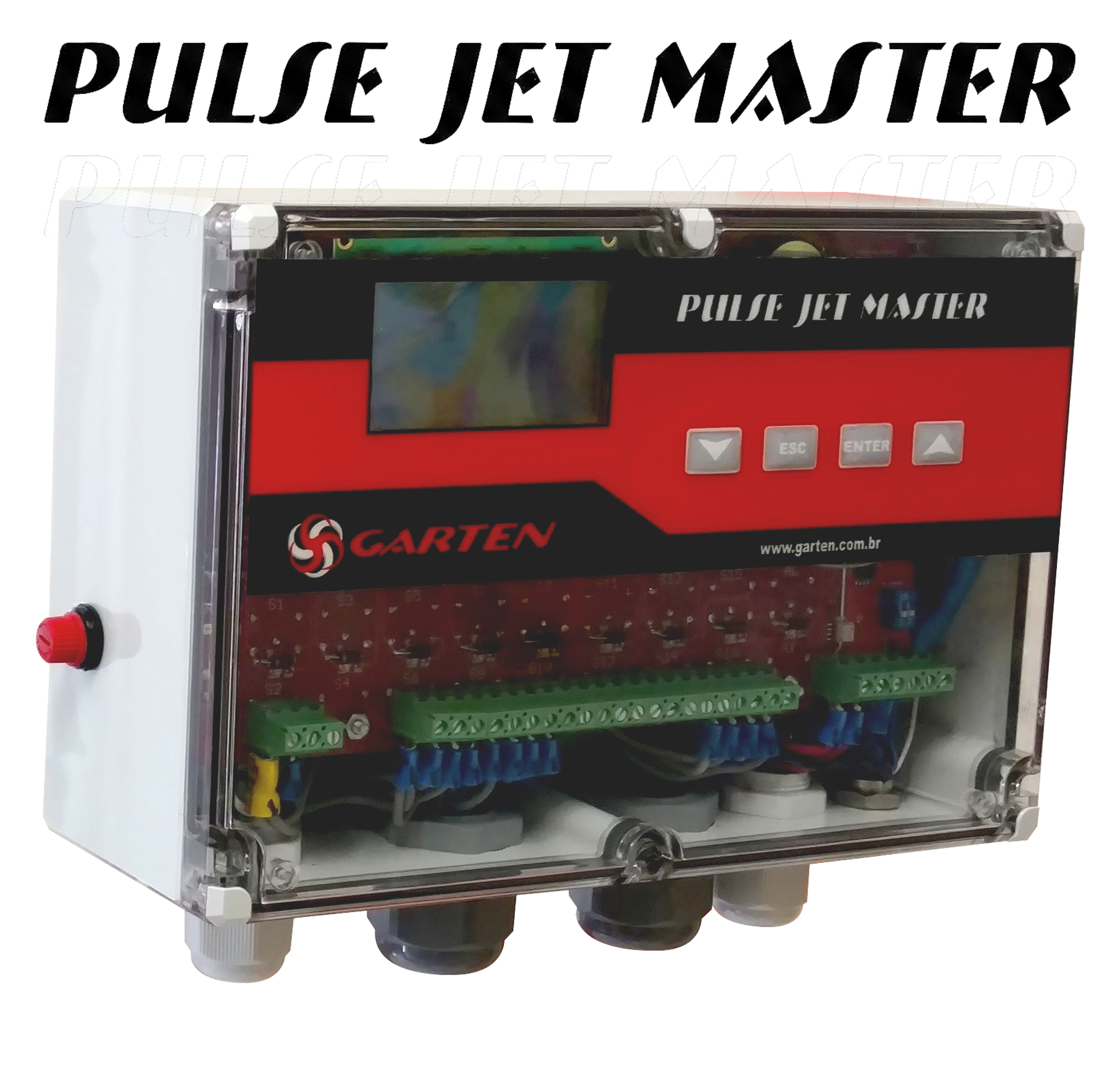

The Pulse Jet Master Control System automates bag filter cleaning with maximum efficiency, activating the valves in an optimized sequence to reduce energy consumption and maintain process performance.

The ROLLKON+ Huller Control System elevates huller management to a new level, automatically measuring pressure, roller diameters, and peripheral speed to ensure maximum efficiency and indicate the exact moment for reversal or replacement.

The Digiplex is Garten’s digital thermometry system, designed to perform precise and organized reading of internal temperatures in silos and storage structures.

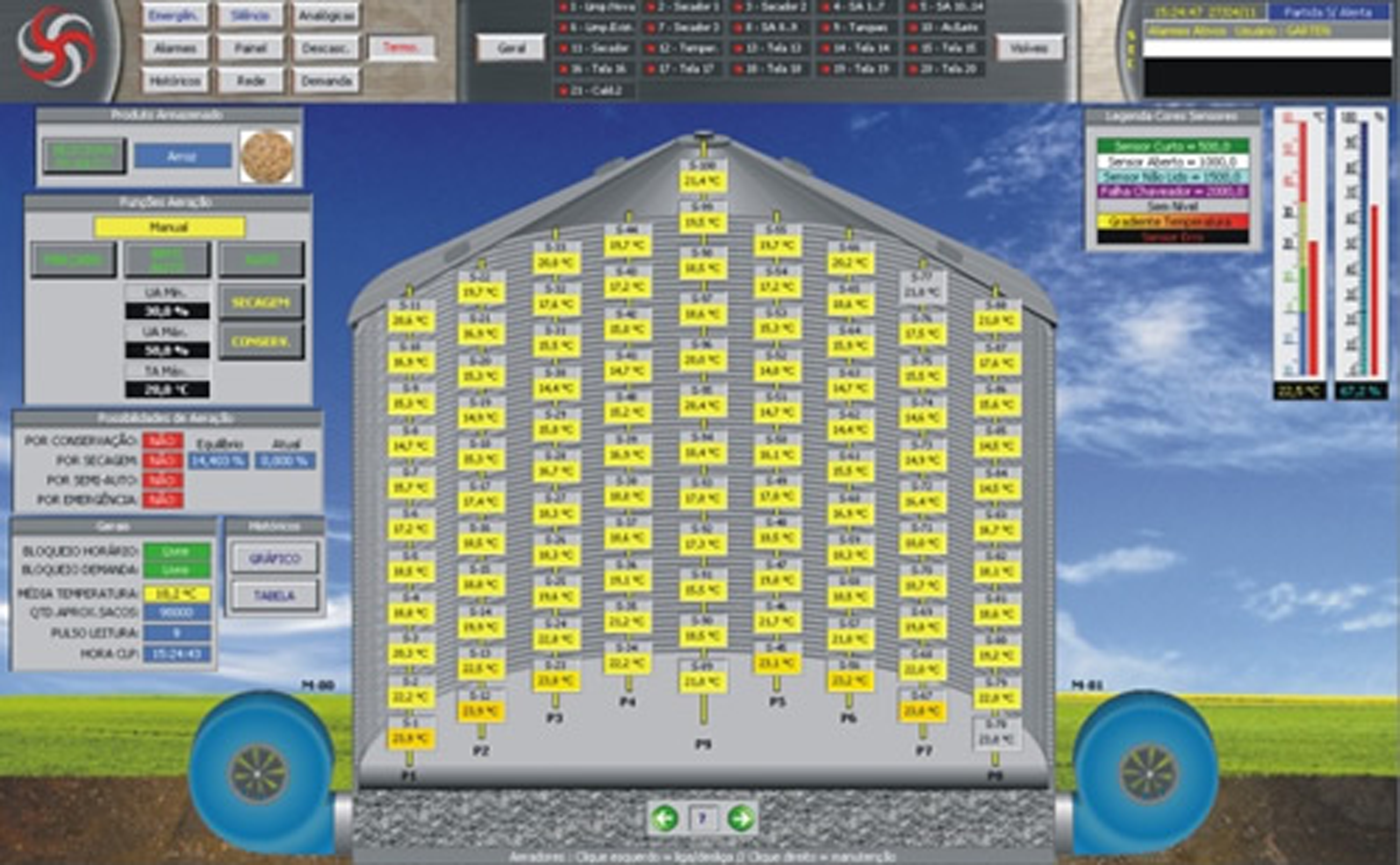

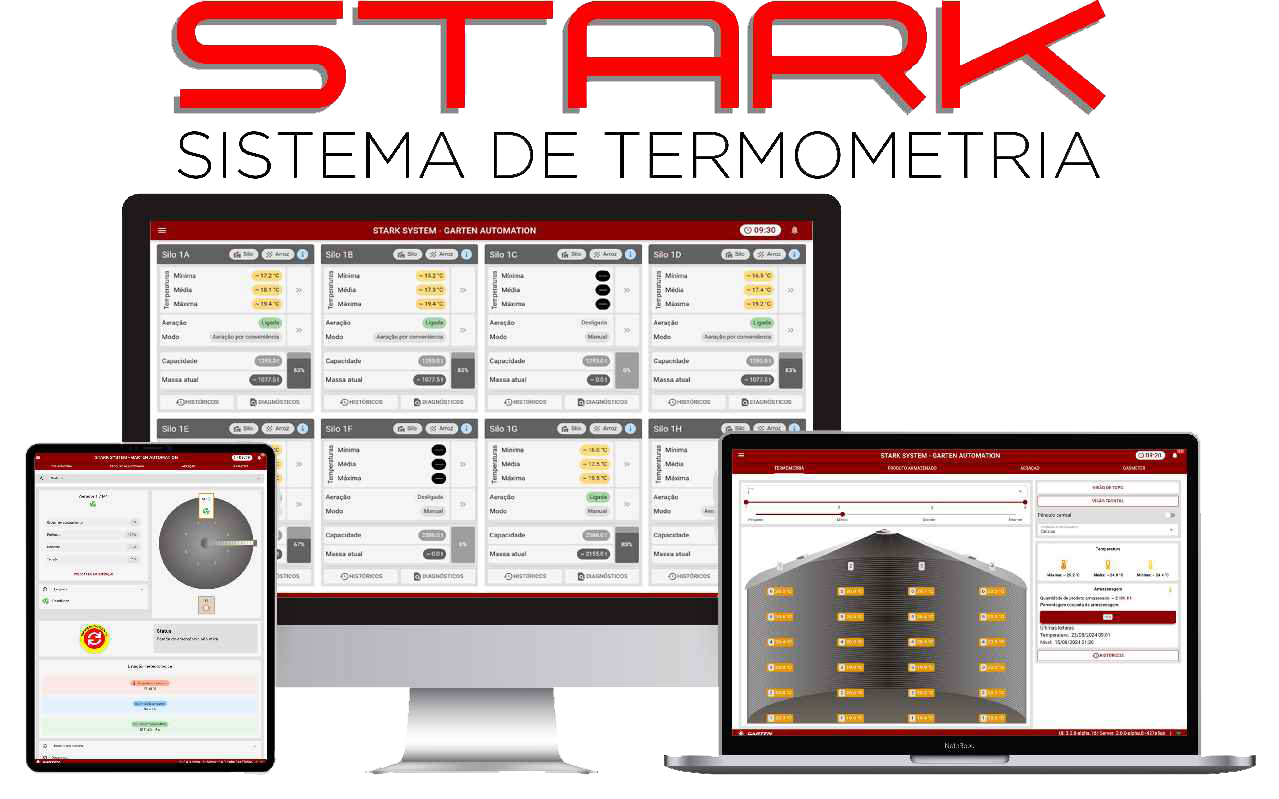

STARK provides complete and intelligent control of grain storage, monitoring temperature, humidity, CO2 and aeration to preserve quality and prevent losses. With advanced automation and 4.0 technology, it enables remote analysis and operation from anywhere in the world.

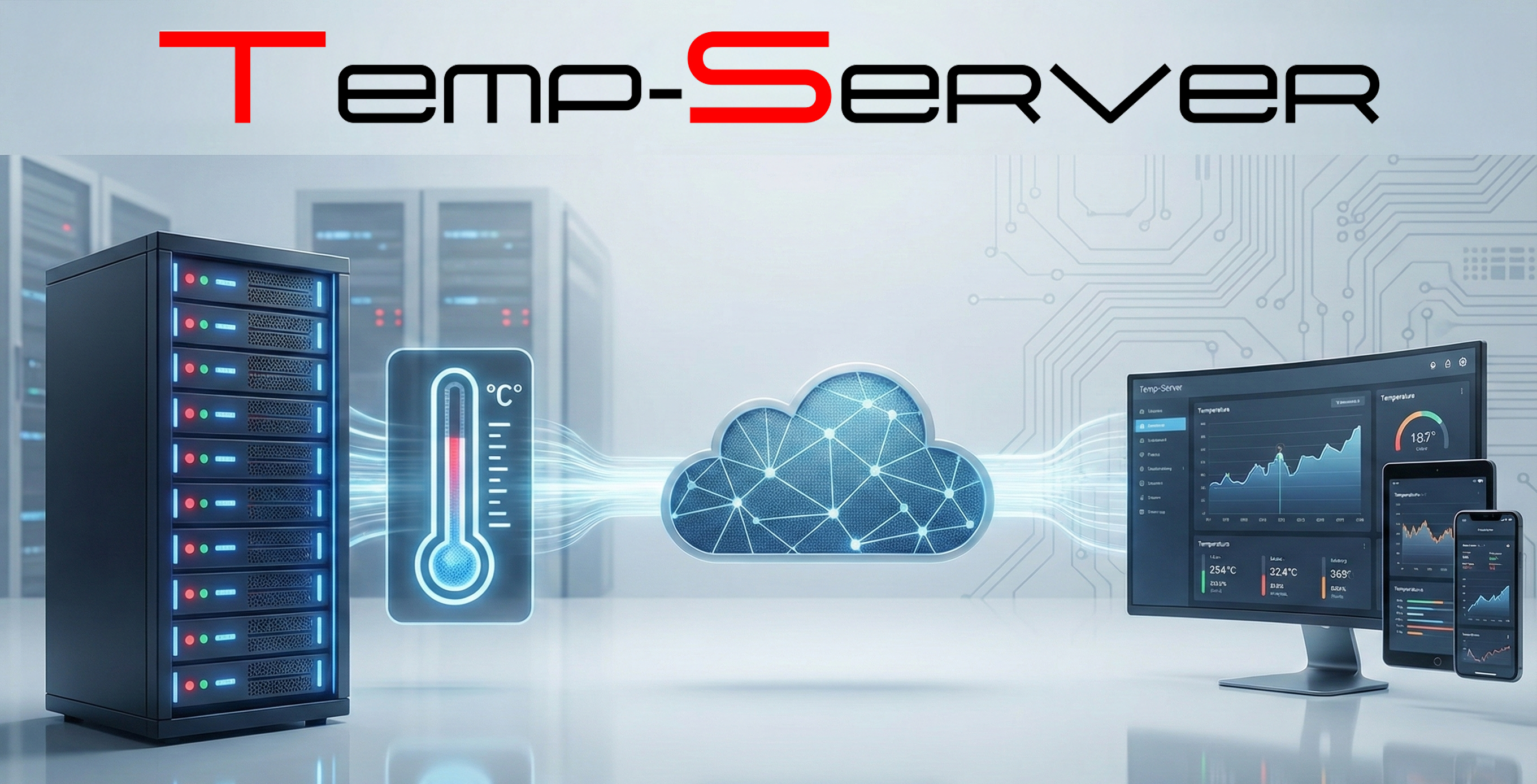

The Temp-Server monitors the temperature of multiple sensors in real time and automatically alerts any anomaly, ensuring safety, stability, and failure prevention in servers. With web access and email notifications, it provides continuous and reliable thermal control.