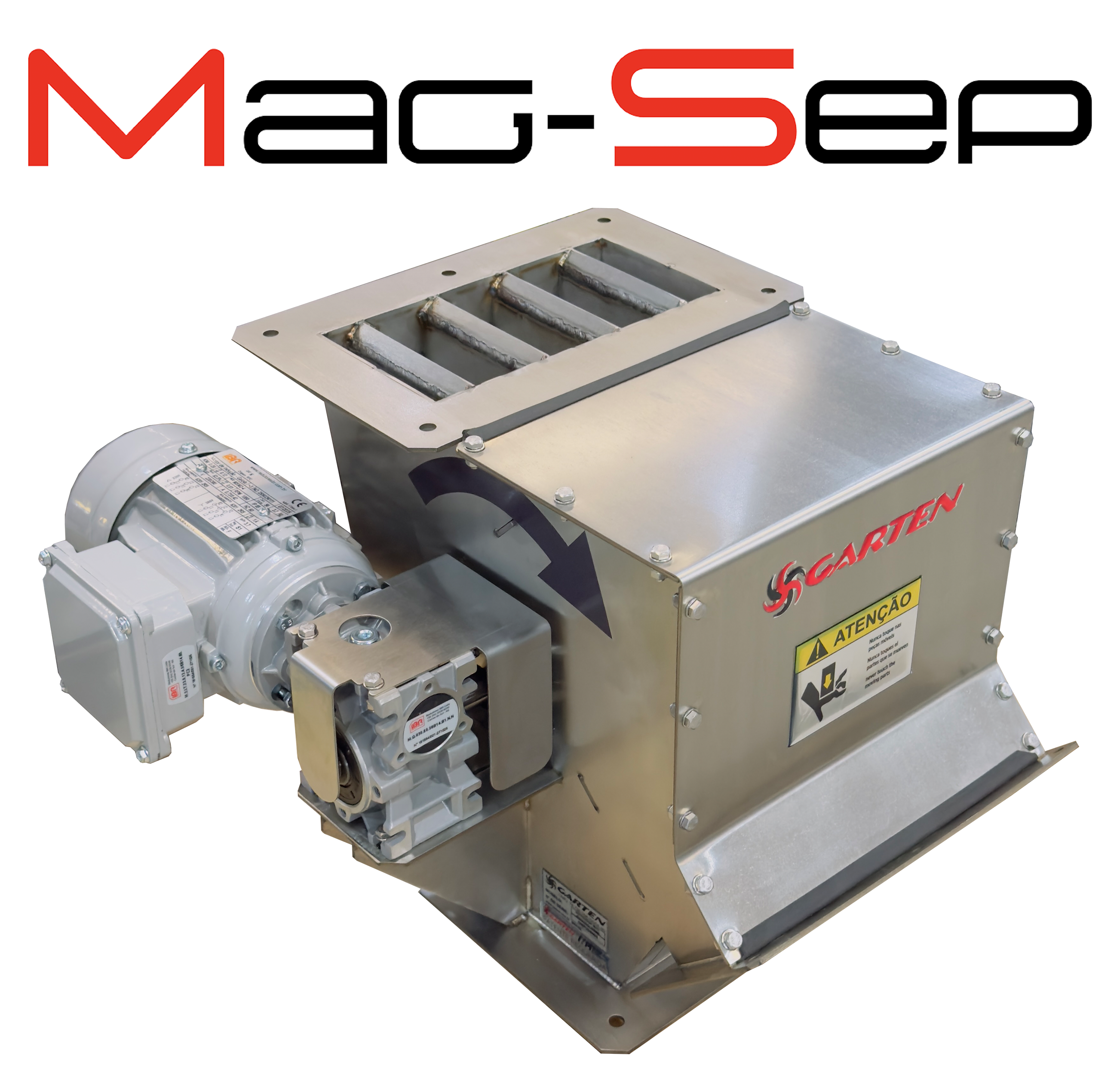

The Mag-Sep is essential protection and purification equipment for the integrity of your processing line. It operates via a continuous cyclic cleaning system, designed to deliver 100% protection and maximum efficiency in the removal of magnetic particles from granular or powder material flows. Installed at strategic points, the unit intercepts gravity-fed material, ensuring constant decontamination without causing downtime or interruptions to the production process.

Its operation relies on discs equipped with high-power Neodymium magnets, generating an intense magnetic field to attract and retain ferrous fragments. Unlike static systems, the Mag-Sep features a rotating shaft driven by a gear motor. This continuous motion prevents "bridging" (flow blockage) and automatically conveys captured metals to a dedicated side outlet, ensuring the equipment remains clean and primed for subsequent capture.

Constructed entirely from stainless steel, the Mag-Sep offers high abrasion resistance and ease of sanitization, complying with the most rigorous industrial standards. With simple integration into plant automation and various capacity models, it is the ideal solution for those seeking operational efficiency and total security against metallic contaminants.

The stated capacities refer to grain flow, varying according to material density and the selected model. In addition to the standard line, Garten develops customized special models, adapting the project to meet each client's specific requirements.

| Model | 9 t/h | 11 t/h | 16 t/h |

| Nominal Capacity | 9 tons/hour | 11 tons/hour | 16 tons/hour |

| Housing Dimensions | 100 x 200 x 300 mm | 100 x 250 x 300 mm | 100 x 350 x 300 mm |

| Inlet Width | 200 mm | 250 mm | 350 mm |

| Disc Quantity | 4 Discs | 5 Discs | 7 Discs |

|

Overall Width (w/ motor) |

~416 mm | ~466 mm | ~566 mm |

FEATURES