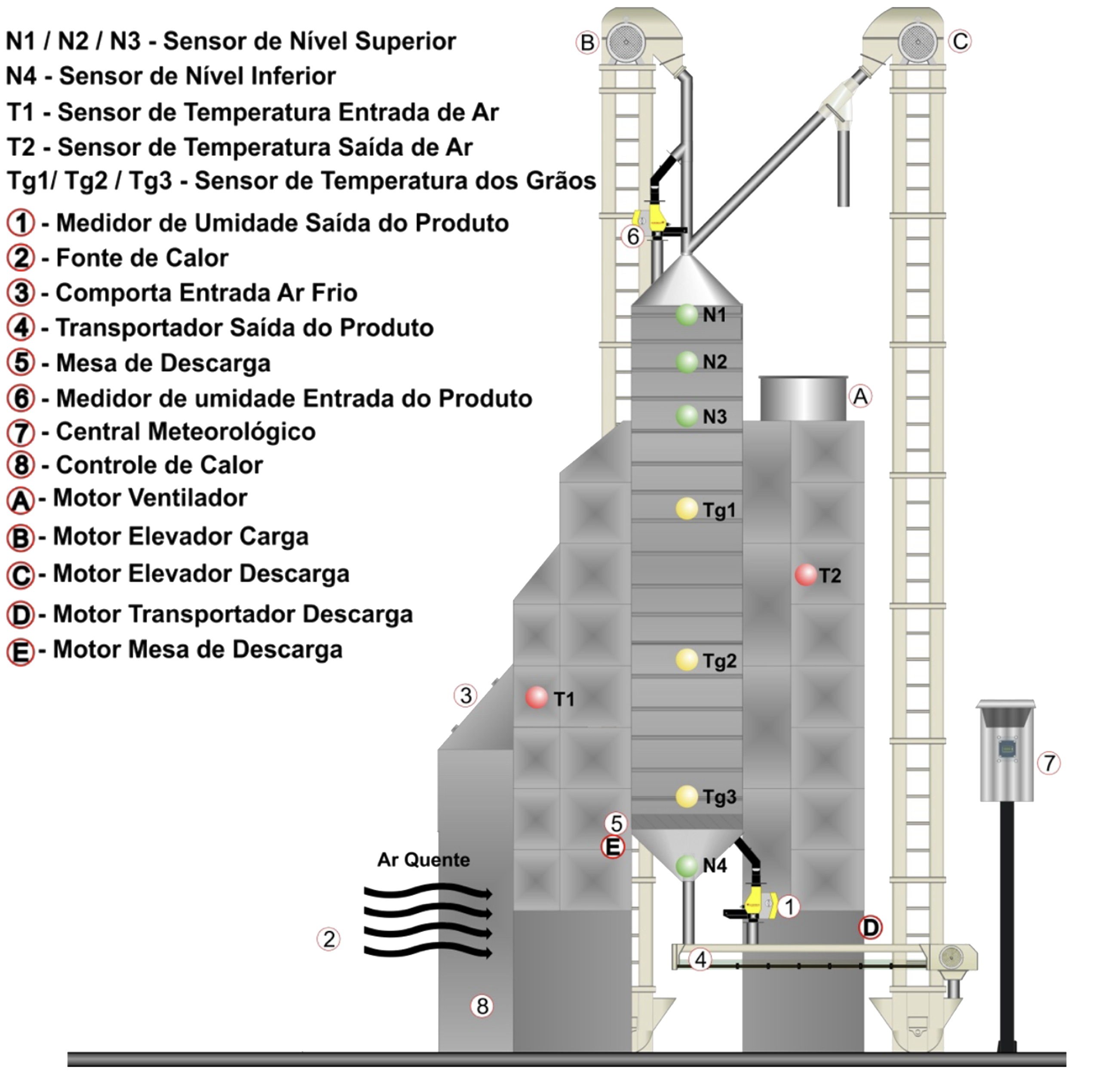

The Dryer Control System from Garten was designed to fully automate the rice drying process, monitoring in real time the critical parameters that determine efficiency and final product quality. The system continuously tracks grain moisture, internal dryer level, inlet and outlet air temperature, grain mass temperature, and the discharge airlock cycle, ensuring that all stages operate within ideal conditions.

The control adapts to both intermittent and continuous dryers: in continuous models, it uses moisture meters at the inlet and outlet; in intermittent models, monitoring is performed directly at the outlet. In addition, the system tracks strategic points throughout the process, such as green and dry rice buffer silos, conveyors, and elevators. With this complete visibility, it prevents instability, overheating, and improper drying, protecting the product and increasing operational efficiency.

The control panel operates on 110/220 VAC and provides 24 VDC for system devices. The solution may include a weather station for climate correlation, gas burner automation, and furnace control for rice husk or wood chips. Ethernet connectivity enables integration with supervisory and corporate systems, providing traceability and precise decision-making. It is a robust, safe system aligned with the demands of modern industrial automation.

FEATURES