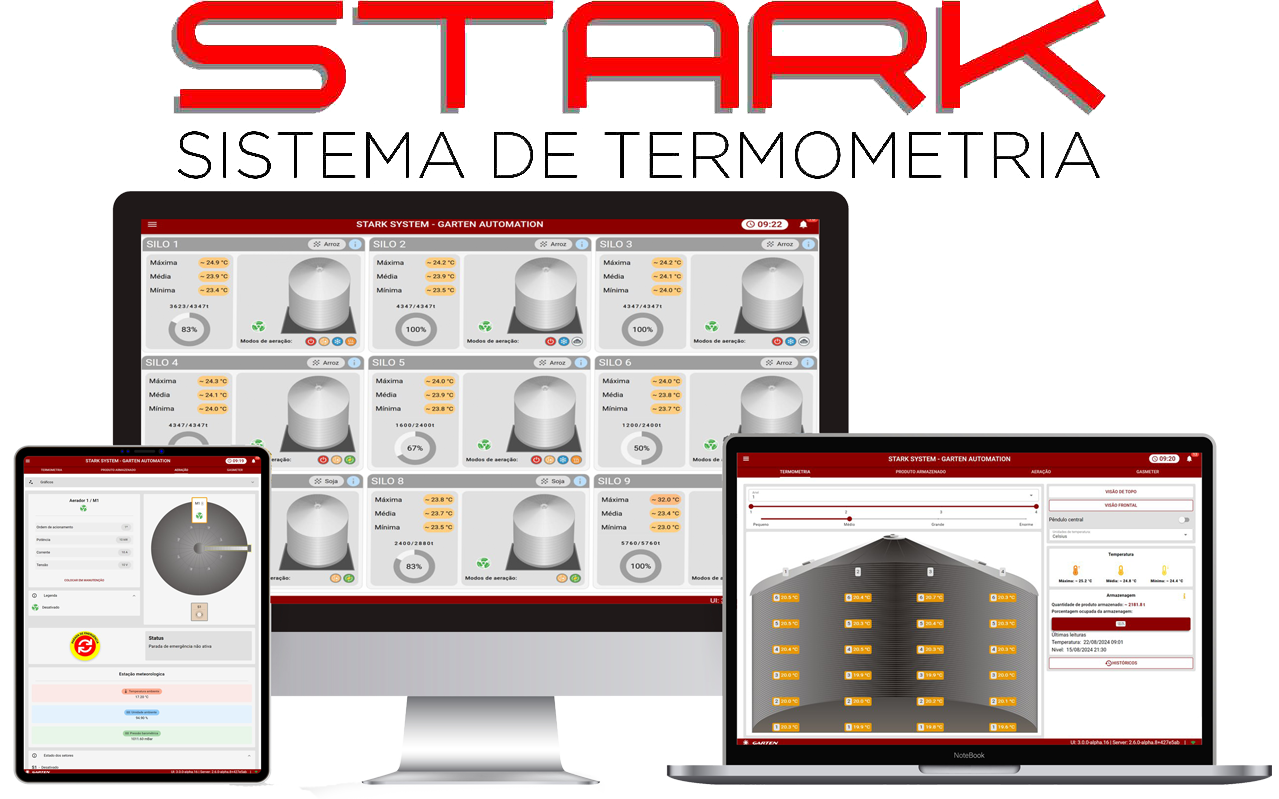

The STARK Garten system offers a complete solution for grain storage, using Industry 4.0 technologies and principles to monitor temperature, CO2 and aeration, ensuring safety, quality and full optimization. With innovative features and embedded technology, the system enables automation, analysis and remote control from anywhere in the world.

STARK provides real-time temperature readings in silos and grain bins using analog or digital sensors. An algorithm calculates the product level based on thermal distribution, while trend-analysis tools identify increases or decreases that indicate risks such as hot spots, deterioration or early infestation. This functionality ensures early diagnostics and continuous protection of grain quality.

The system automatically controls aerators to reduce humidity, temperature or the product’s cellular respiration. Operators can set shutdown criteria by time, energy limits or specific conditions. Dedicated charts display the evolution of grain conservation and highlight situations that favor fungi, sprouting or insect proliferation. Aeration automation optimizes resources and preserves the stored product.

The CO2 sensor detects anomalies up to five weeks before temperature sensors show noticeable changes. This anticipation significantly reduces losses caused by fungi, insects or other factors that affect grain quality. Continuous CO2 monitoring adds an essential layer of safety to the process.

All information is recorded in a dedicated database, enabling comprehensive reports, audits and data-driven decision-making. STARK automatically documents every action—whether performed by automation or users—ensuring complete control and traceability. The interface offers clear and quick data visualization, making storage monitoring easier.

The system tracks the energy usage of aerators, allowing operators to identify waste and optimize resource use. This functionality helps reduce operational costs and increases the plant’s energy efficiency.

With embedded technology and 4.0 principles, STARK can be accessed and controlled from anywhere in the world. This connectivity supports strategic decisions, remote inspections and continuous operational oversight, giving managers total visibility over storage operations.