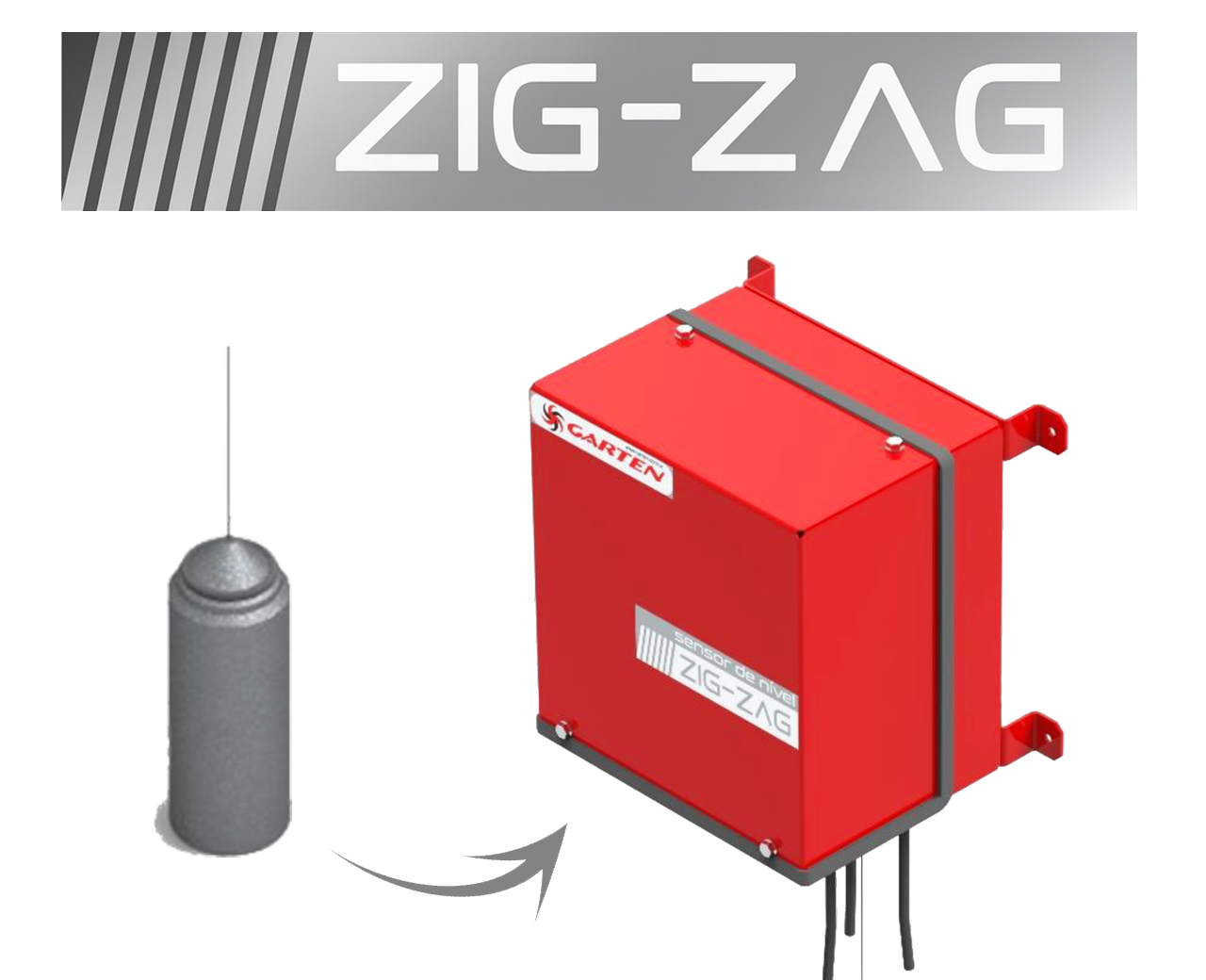

The ZIG-ZAG is Garten’s level sensor designed to identify the height of the product inside silos, bins, overhead tanks, conical silos, and storage silos. Installed at the top of these structures, it uses a pendulum that descends to the grain surface and returns to its origin point, allowing the system to determine the material height and, consequently, the approximate stored volume at the time of measurement.

The pendulum’s movement — including measurement time and cycle interval — is fully programmable, allowing the operation to be configured according to each process’s needs. Readings can be sent directly to the automation system, ensuring efficient plant integration and making stock monitoring easier. The ZIG-ZAG also supports reading via computer or existing systems, offering flexible communication via Modbus RTU RS485.

Built with a fully shielded body, the ZIG-ZAG is designed to operate in environments with high dust concentration while maintaining consistent performance and long service life. All grain-contact components are made of stainless steel, preventing equipment damage and eliminating any risk of contamination of the stored product.

Integrable with databases and operating with standard industrial power supply, the ZIG-ZAG is a robust and reliable solution for precise level monitoring in grain storage systems.

FEATURES