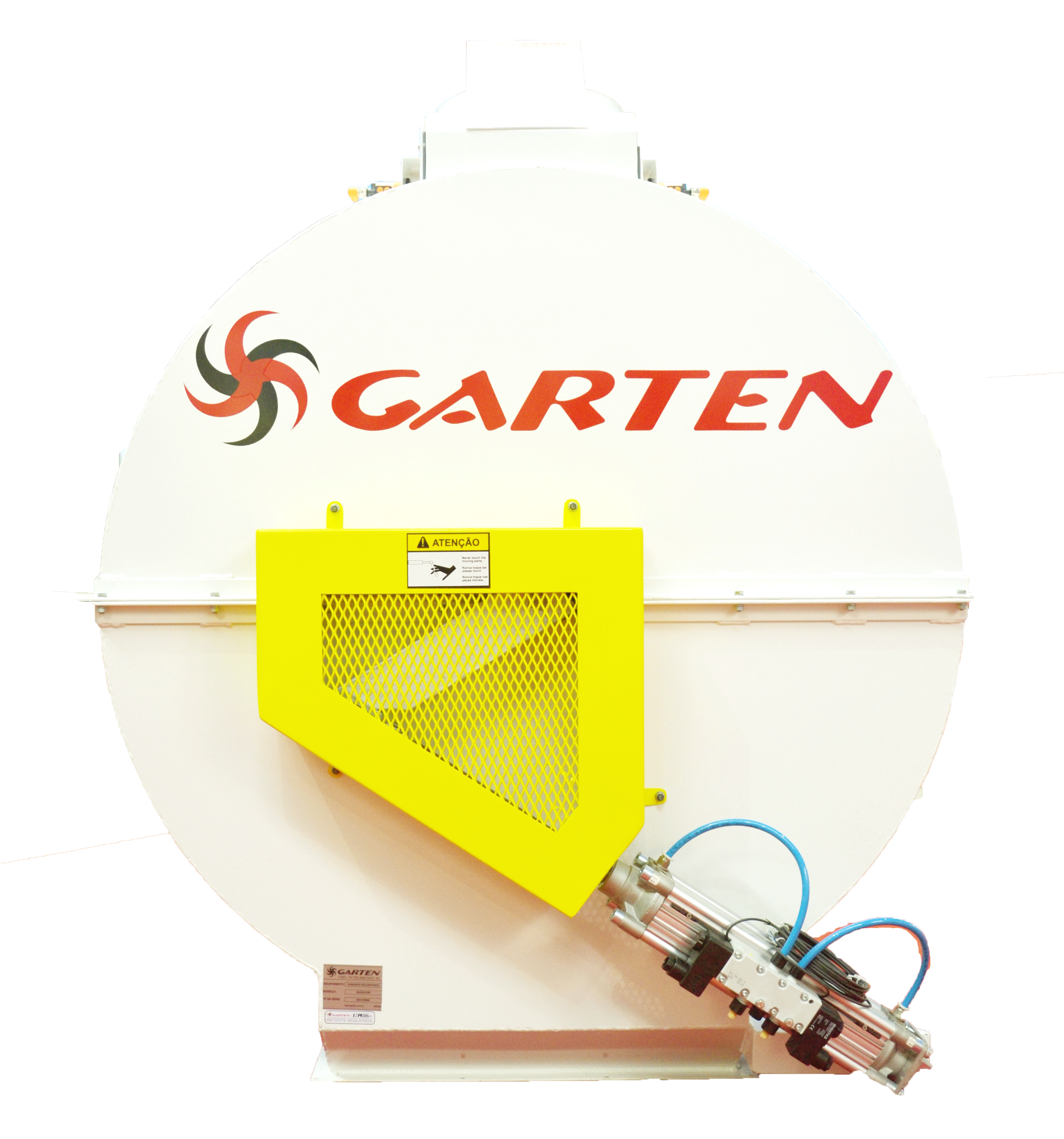

The Volumetric Feeder is a device designed to accurately and continuously measure the volume of grains in industrial processes. Built from carbon-steel sheet with powder-coated epoxy paint, it offers high resistance and long durability even in demanding operating environments. Inside the equipment, there is a split damper driven by a pneumatic cylinder, which performs volumetric counting based on the level sensor reading, ensuring repeatability and stability throughout the process.

In continuous-flow applications, the Volumetric Feeder measures volumes of up to 40 tons per hour, preventing common issues found in systems based solely on weight—such as shortages or overflow caused by variations in the grains’ specific weight. In the parboiling process, it is especially used to control the volume of paddy rice entering the soaking tanks, ensuring that each tank receives exactly the same amount and maintaining process uniformity.

For proper operation, the equipment requires clean and dry compressed air and functions exclusively when integrated with Garten’s automation system. Electrical power is supplied at 24 VDC, and its commercialization is linked to the automation package, ensuring full compatibility and consistent performance.

FEATURES