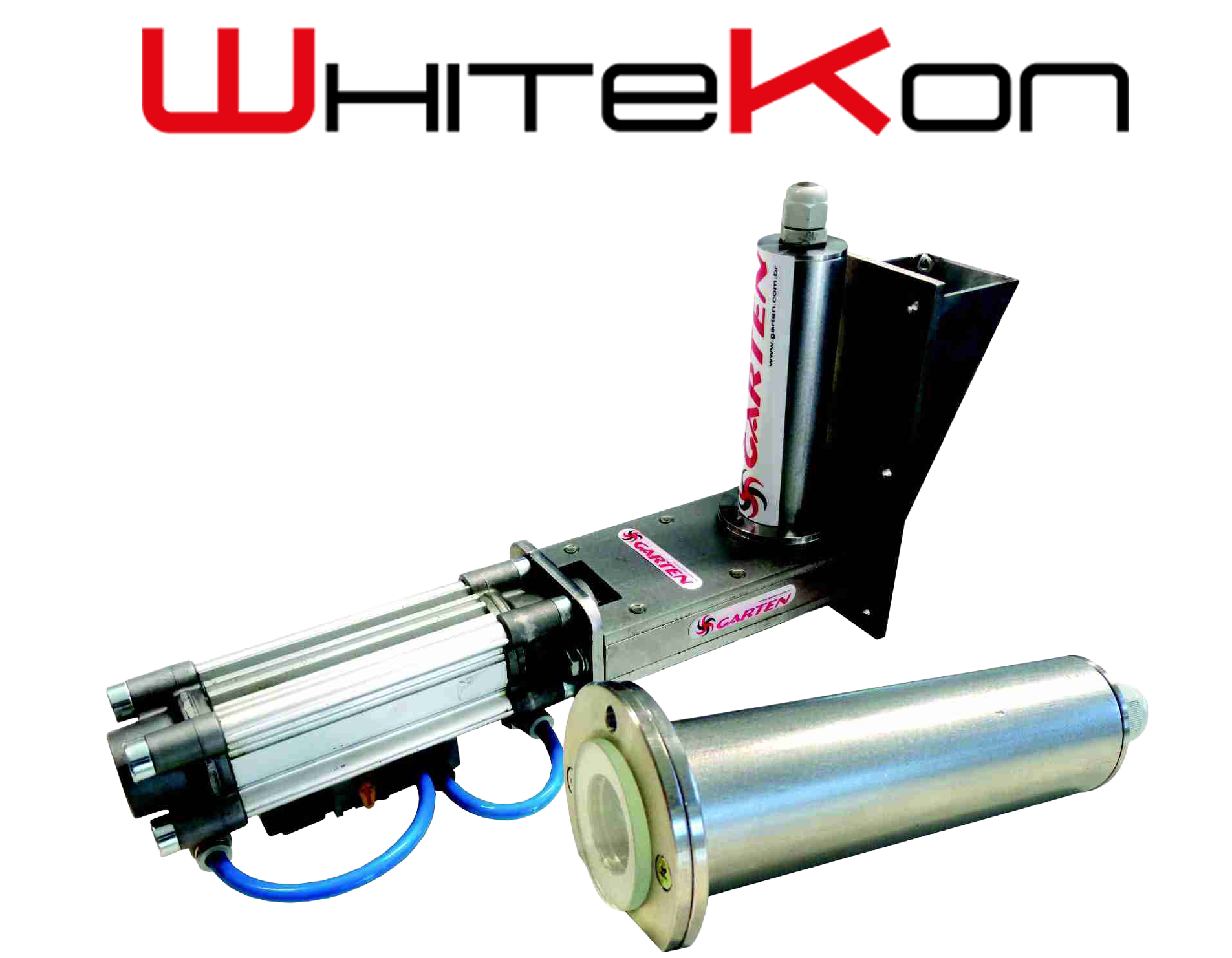

The WhiteKon is Garten’s whiteness meter, designed to collect rice samples and measure whiteness levels directly at the outlet of whiteners and polishers. Equipped with an RGB sensor capable of interpreting any color — with performance optimized for shades between white and yellow — the WhiteKon ensures precise and stable readings even under challenging industrial conditions.

Its microprocessed control system uses digital filters to perform statistical calculations, considering averages and standard deviations to generate highly reliable results. All operations are managed by a PLC, while the touchscreen HMI control panel allows operators to view whiteness measurements, monitor equipment status, and make adjustments quickly and clearly.

The WhiteKon operates independently when controlling measurement, sample collection, and machine adjustments, communicating with the rest of the automation system via Modbus RTU RS485. External integration can be achieved through an Ethernet network, enabling connection to databases, SCADA systems, and management platforms.

To operate, the system requires clean, dry compressed air at approximately 7.0 bar (100 psi) and a standard industrial power supply. Pneumatic, electrical, and mechanical components must be installed according to the plant design, and the control panel can support up to four WhiteKon units depending on operational needs.

Robust, precise, and fully integrated, the WhiteKon provides continuous whiteness monitoring, ensuring process consistency and greater control over final product quality.

FEATURES