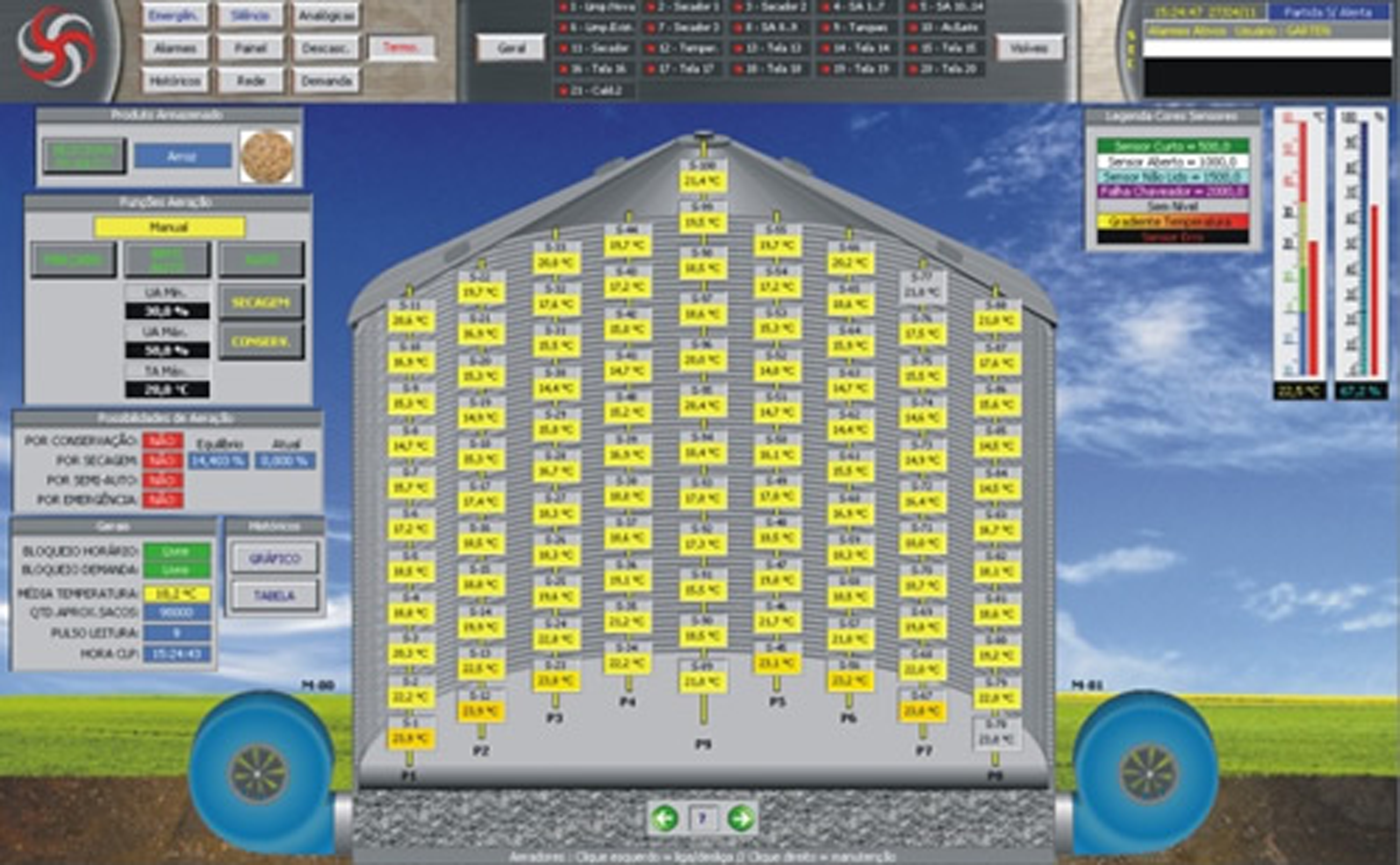

The Garten stored-grain control system was developed with embedded technology and fully automatic operation, integrating advanced resources for analyzing grain behavior and storage conditions. Within this setup, the Thermocouple Sensor Reading Switches ensure continuous and precise thermal monitoring in silos, enabling organized and reliable temperature readings throughout the entire grain mass. The combination of the control software with the switches ensures comprehensive microclimate management, pest prevention, and preservation of the stored product’s quality.

The system interprets each value measured within the grain mass and tracks its variations over time, identifying trends that directly affect the health, moisture, and behavior of the stored product. Using a physical-mathematical modeling algorithm based on the Thompson method, the system determines the product level and estimates moisture across the different layers — from the bottom to the top of the silo — providing a complete picture of the internal conditions.

By integrating the switches into the Garten thermometry system, it becomes possible to anticipate and prevent conditions that favor the development of fungi, insects, and other contaminants. In this way, the switches make monitoring more efficient, precise, and reliable, preserving the grain’s final quality and ensuring safe storage throughout the entire cycle.

Characteristics

- Drying–Aeration System: In this system, the product can be introduced into the silos with up to 17% moisture and reduced to the desired programmed value through the use of aerators.

- Moisture Reduction: Daily monitoring of the moisture reduction of the stored product, without the need for sampling.

- Product Level: Determines the product level inside the silos, eliminating the need for manual volume calculations.

- Humidity and Temperature Control: Allows control of relative air humidity and ambient temperature through a weather station.

- Scanning System: Enables evaluation of the sensors inside the silos, using for control purposes only those that are immersed in the grain mass.

- Electrical Energy: Saves electrical energy by operating the aerators only when necessary and blocking their operation during peak periods, when energy costs are higher.

- Database: It includes a database that stores all information generated by the system, such as thermometric cable temperatures, ambient temperature, ambient humidity, activation of each aerator, operator commands, and system alerts. This allows the entire storage period to be analyzed at any time, while also serving as a proof of product quality.

- Operation: Easy and intuitive commands.

- Control System: Based on large-capacity Siemens Programmable Logic Controllers.

- Connection: Allows secure internet connection for monitoring or integration with a database.

- Product Control System: Eliminates losses caused by excessive aeration by controlling the temperature within the grain mass together with data read by the Weather Station. This system operates considering all available data, such as:

– Aerator design specifications (airflow and pressure).

– Temperature of each sensor inside the grain mass.

– Ambient temperature.

– Relative air humidity.

– Product level inside the silo and its quantity.