The Garten Gate was developed to efficiently control the flow in the processing line, functioning as a regulator or feeder of grains according to operational needs. Its advanced pneumatic actuation concept allows automatic closing during power outages, protecting the equipment connected to the flow and preventing blockages that could compromise production.

Its self-cleaning design prevents product buildup between articulated parts, ensuring continuous operation even in high-demand environments. The gate can be applied at various points in the plant, such as silos, boxes, tanks, and conveyors, and integrates easily with existing automation systems connected to PLCs.

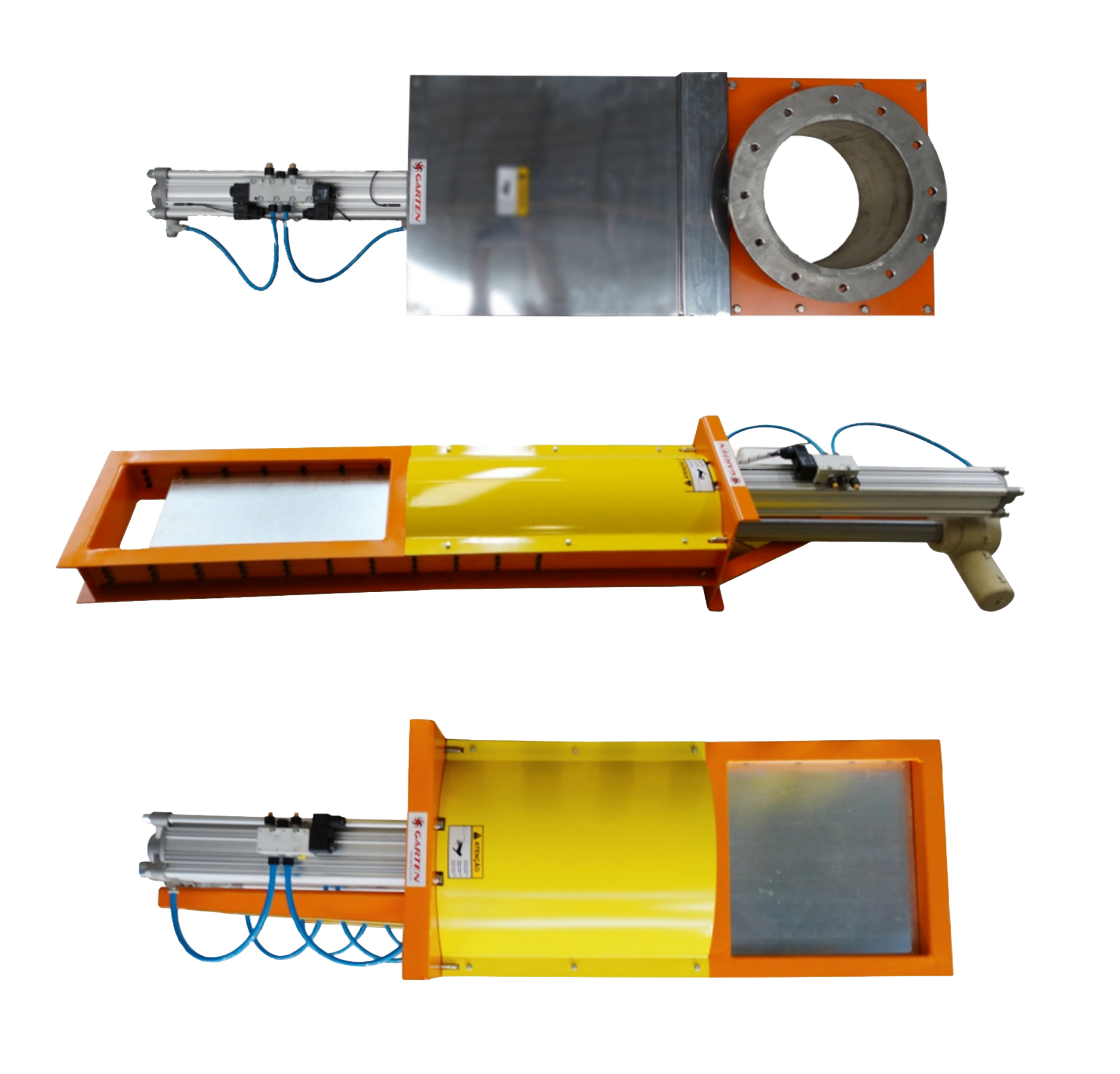

The product line includes three versions: the Pneumatic On/Off model, used for direct opening and closing of inlets and outlets; the Cylindrical Pneumatic On/Off model, recommended for discharging soaked rice in parboiling tanks; and the Proportional model, which modulates flow according to local demand. In more advanced configurations, the gate may include stepper motor positioning control, with manual or automatic operation via HMI and MODBUS communication. This version also incorporates a battery system for emergency operation and safe closing in case of power loss.

The parts subject to greater wear receive galvanization treatment, while the remaining surfaces use industrial synthetic enamel paint. Custom-built, it fully complies with NR-12 standards and delivers reliability, safety, and performance in continuous-flow operations.

FEATURES