The switching units organize the sequential reading of temperatures in silos, ensuring continuous thermal monitoring, real-time analysis, and the prevention of conditions that affect the quality of stored grains.

The GasMeter detects, with extreme advance notice, any abnormal increase in the cellular respiration of grains in the silo, alerting even weeks before a temperature rise occurs. With full integration into the STARK system, it ensures improved preservation and reduces storage losses.

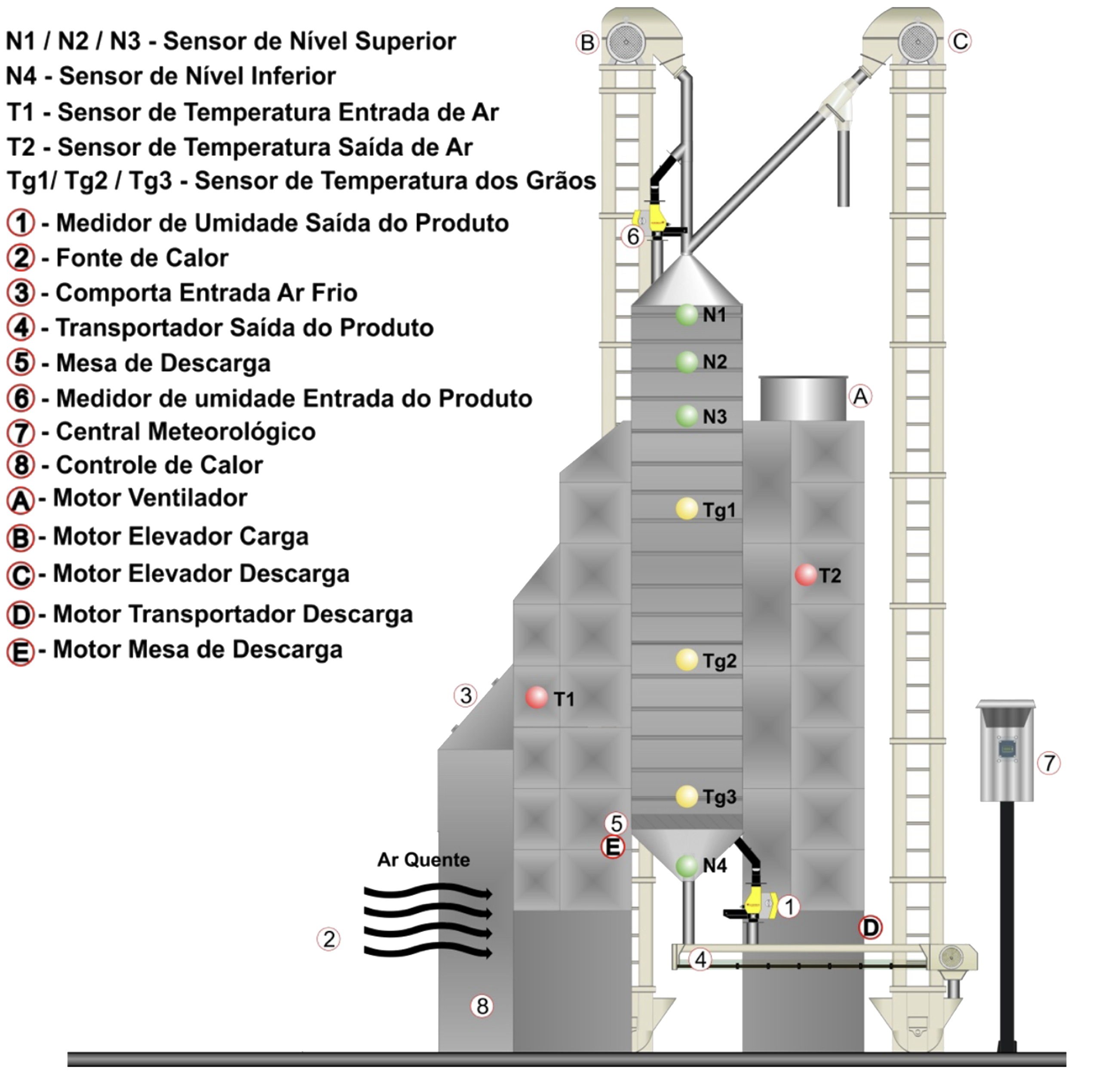

The Dryer Control System automates the entire drying process, monitoring moisture, temperature, and grain flow to ensure continuous, efficient, and fully stable operation. With comprehensive supervision and industrial integration, it ensures superior final quality and maximum process safety.

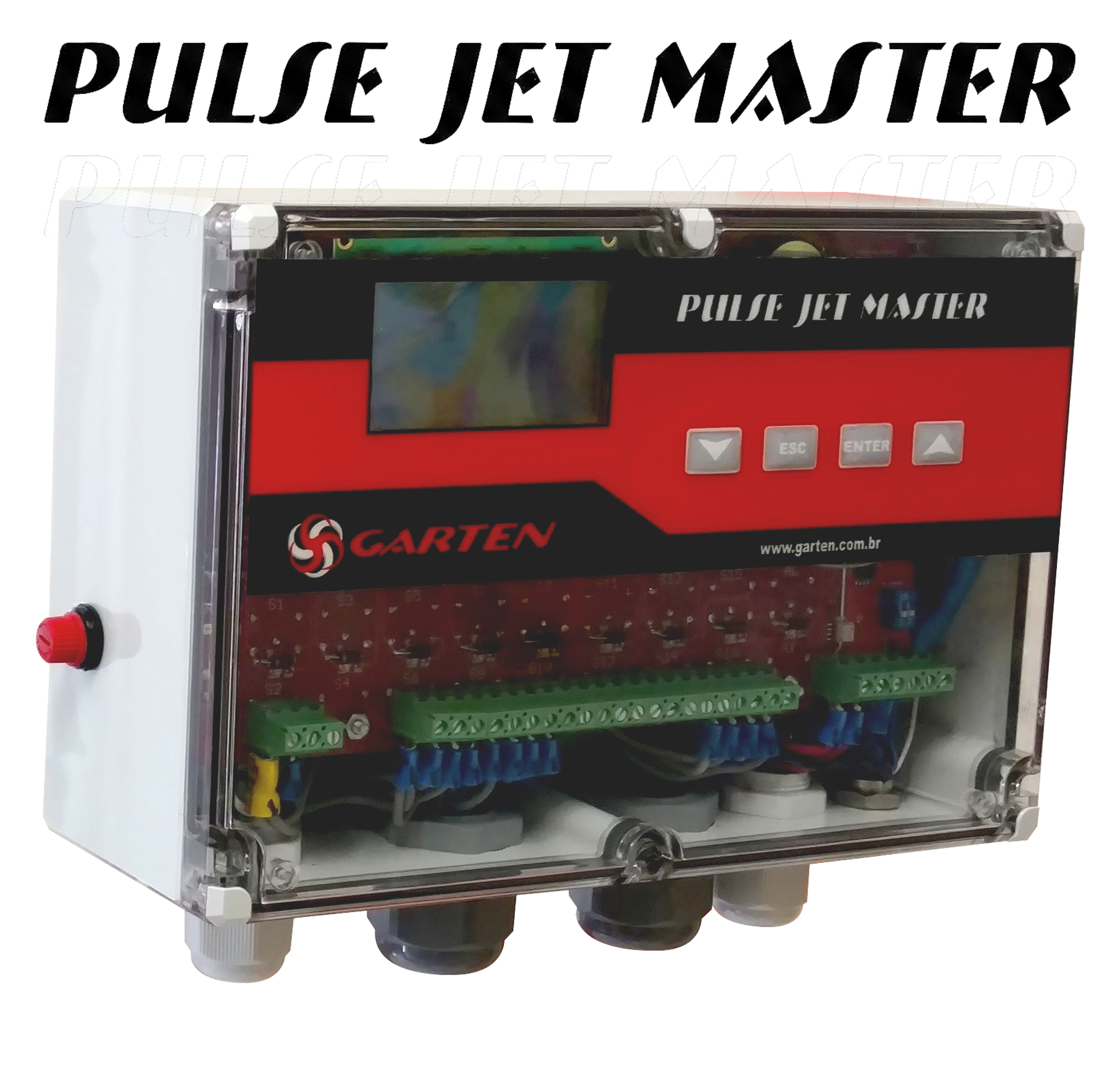

The Pulse Jet Master Control System automates bag filter cleaning with maximum efficiency, activating the valves in an optimized sequence to reduce energy consumption and maintain process performance.

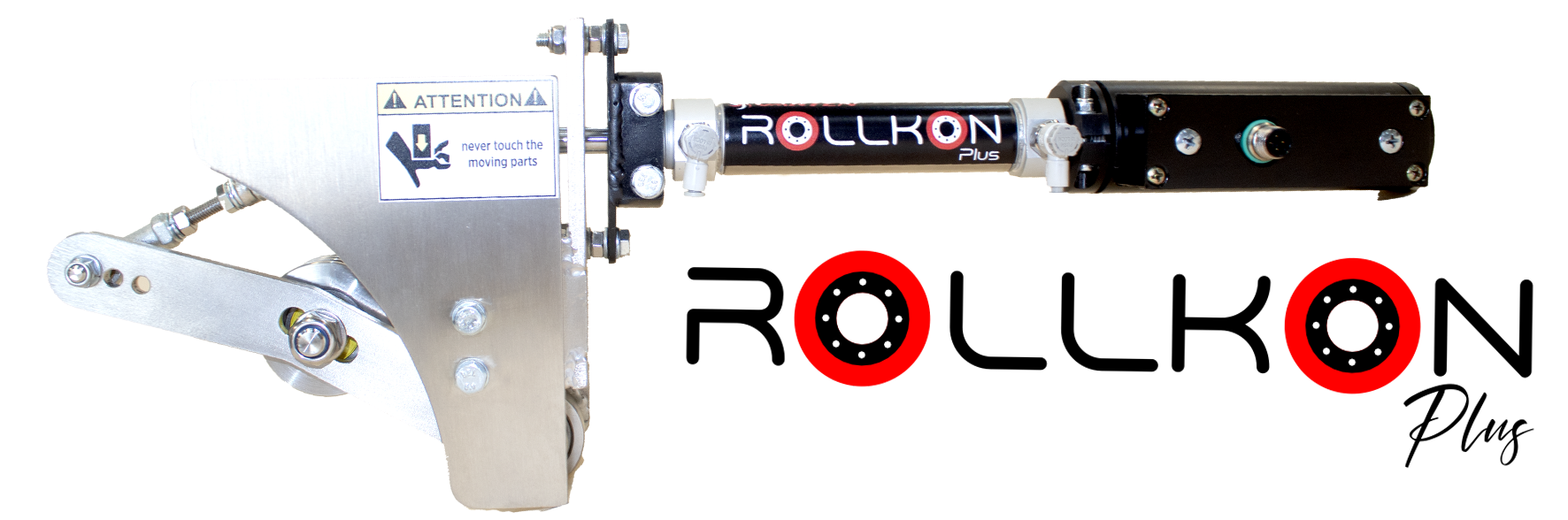

The ROLLKON+ Huller Control System elevates huller management to a new level, automatically measuring pressure, roller diameters, and peripheral speed to ensure maximum efficiency and indicate the exact moment for reversal or replacement.

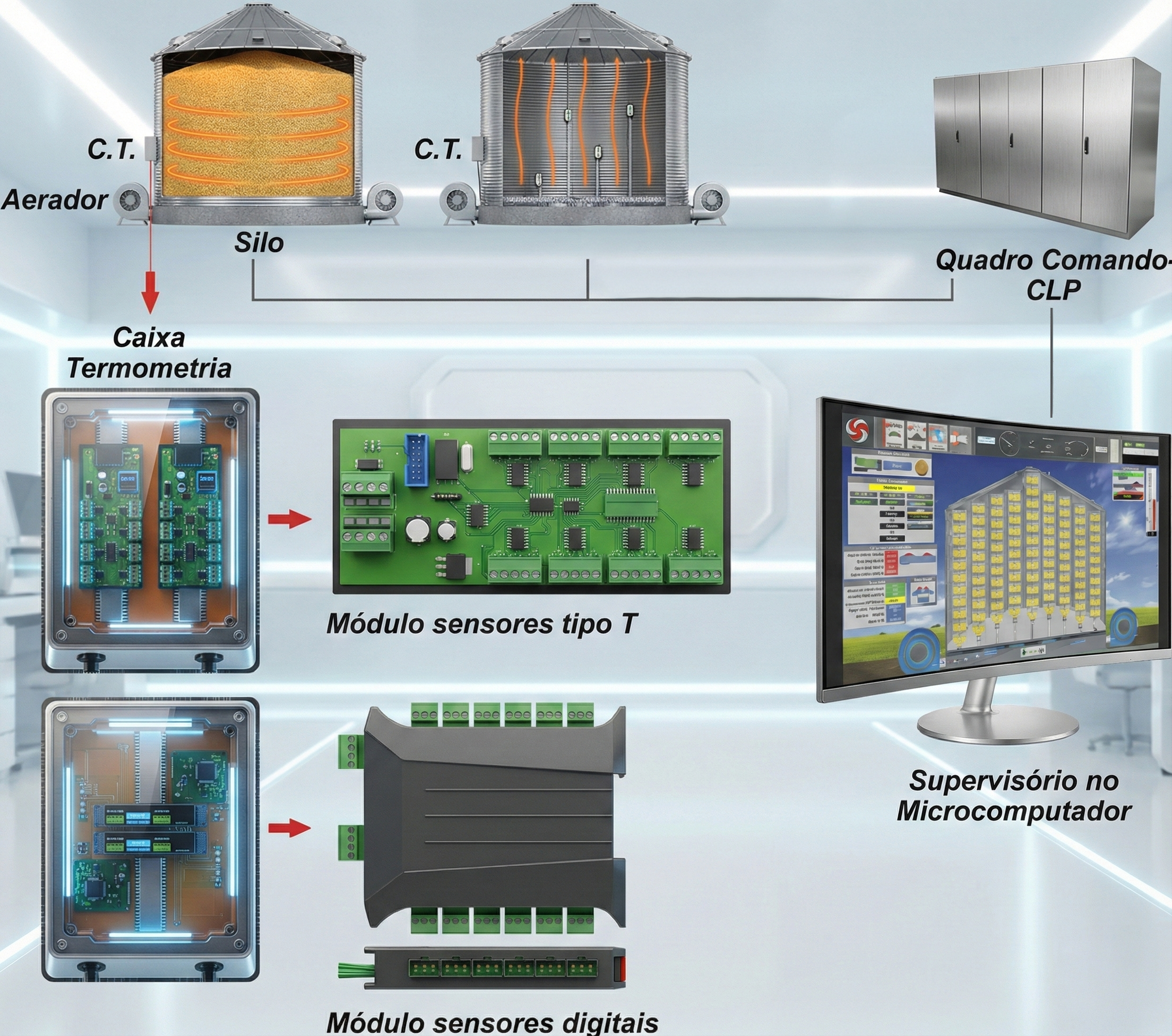

The Digiplex is Garten’s digital thermometry system, designed to perform precise and organized reading of internal temperatures in silos and storage structures.

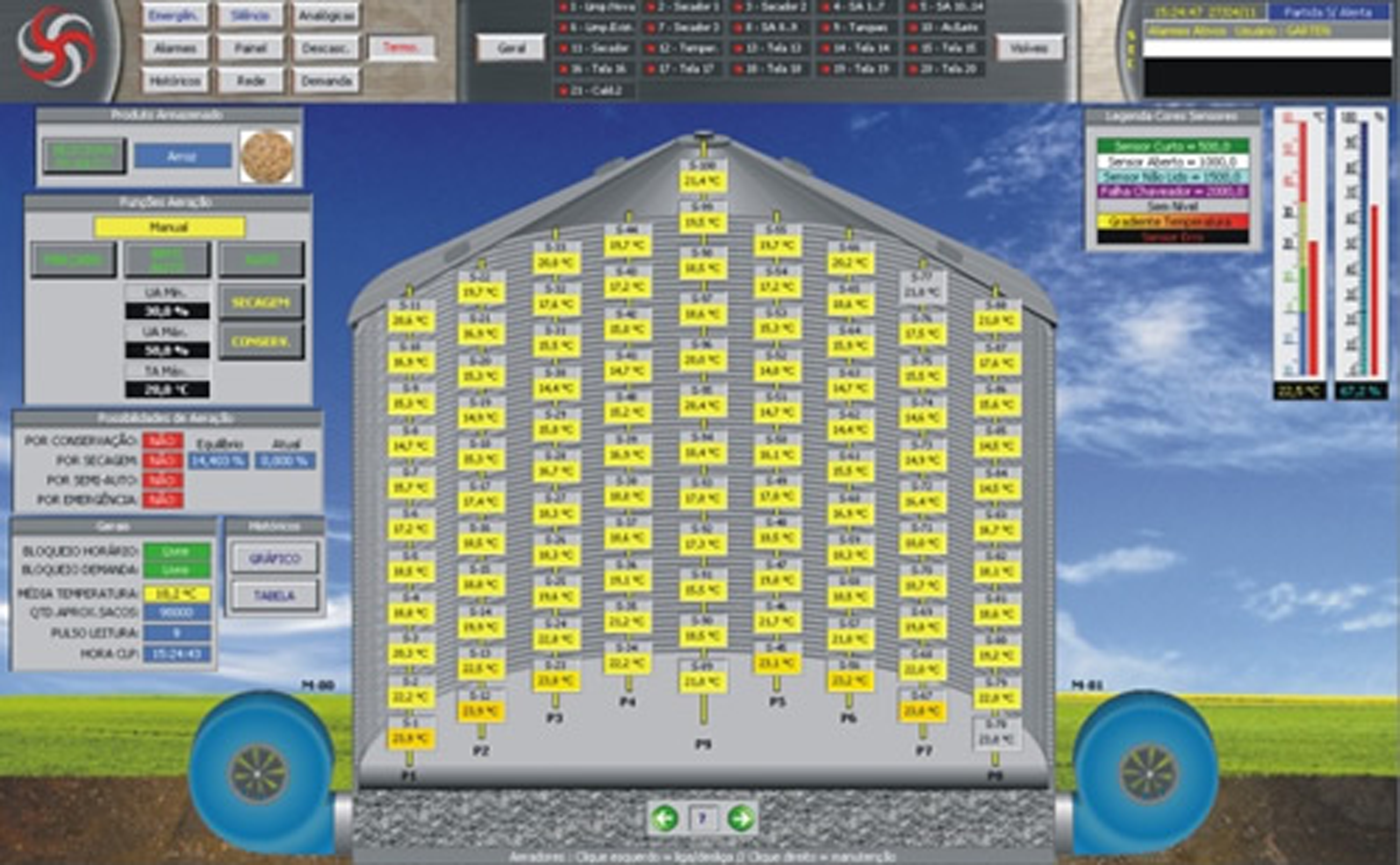

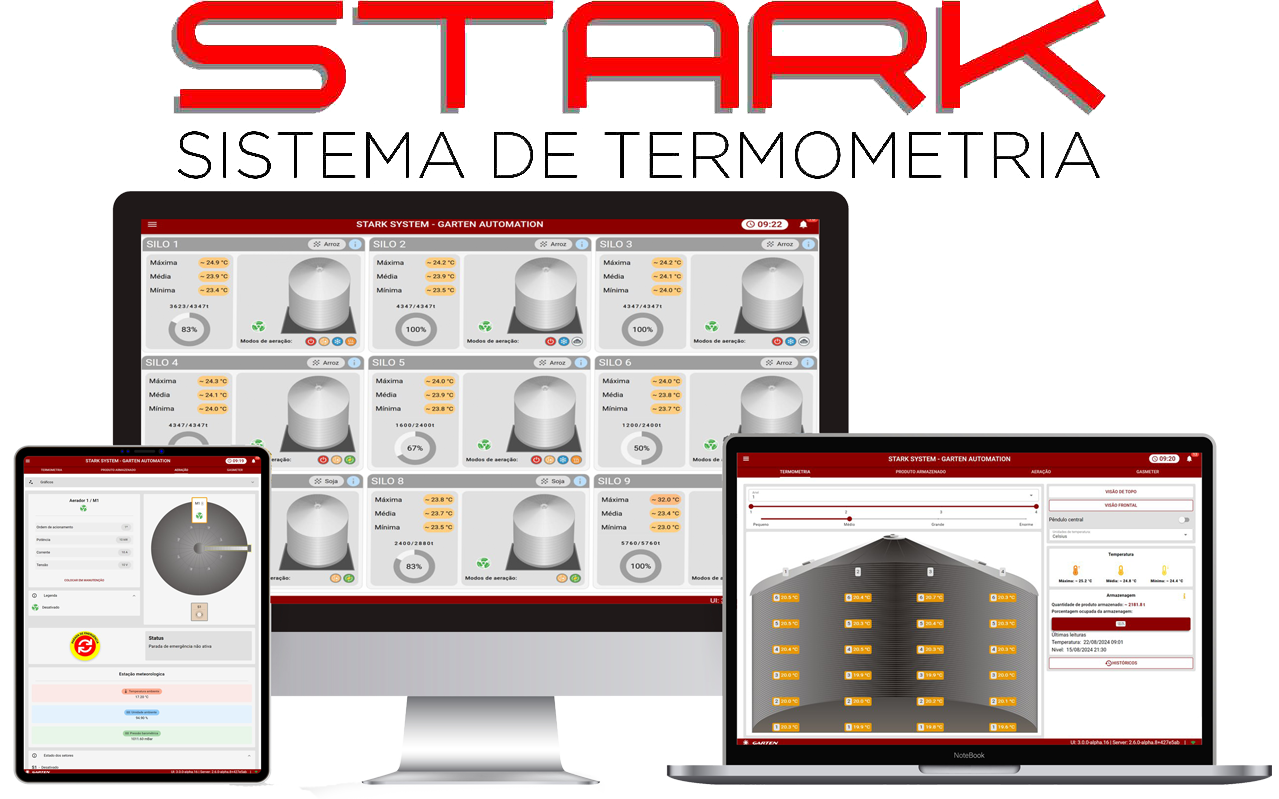

STARK provides complete and intelligent control of grain storage, monitoring temperature, CO2 and aeration to preserve quality and prevent losses. With advanced automation and 4.0 technology, it enables remote analysis and operation from anywhere in the world.

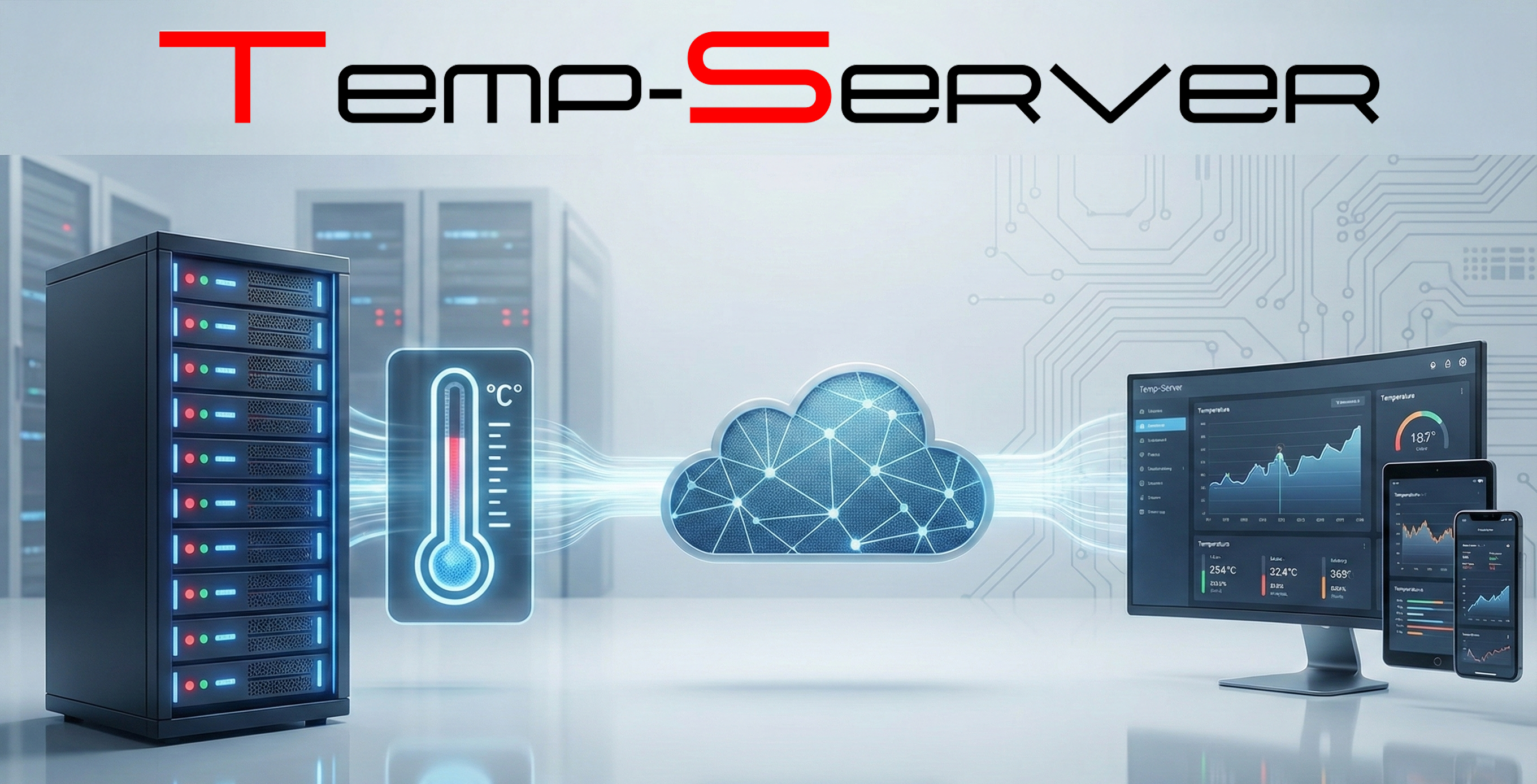

The Temp-Server monitors the temperature of multiple sensors in real time and automatically alerts any anomaly, ensuring safety, stability, and failure prevention in servers. With web access and email notifications, it provides continuous and reliable thermal control.