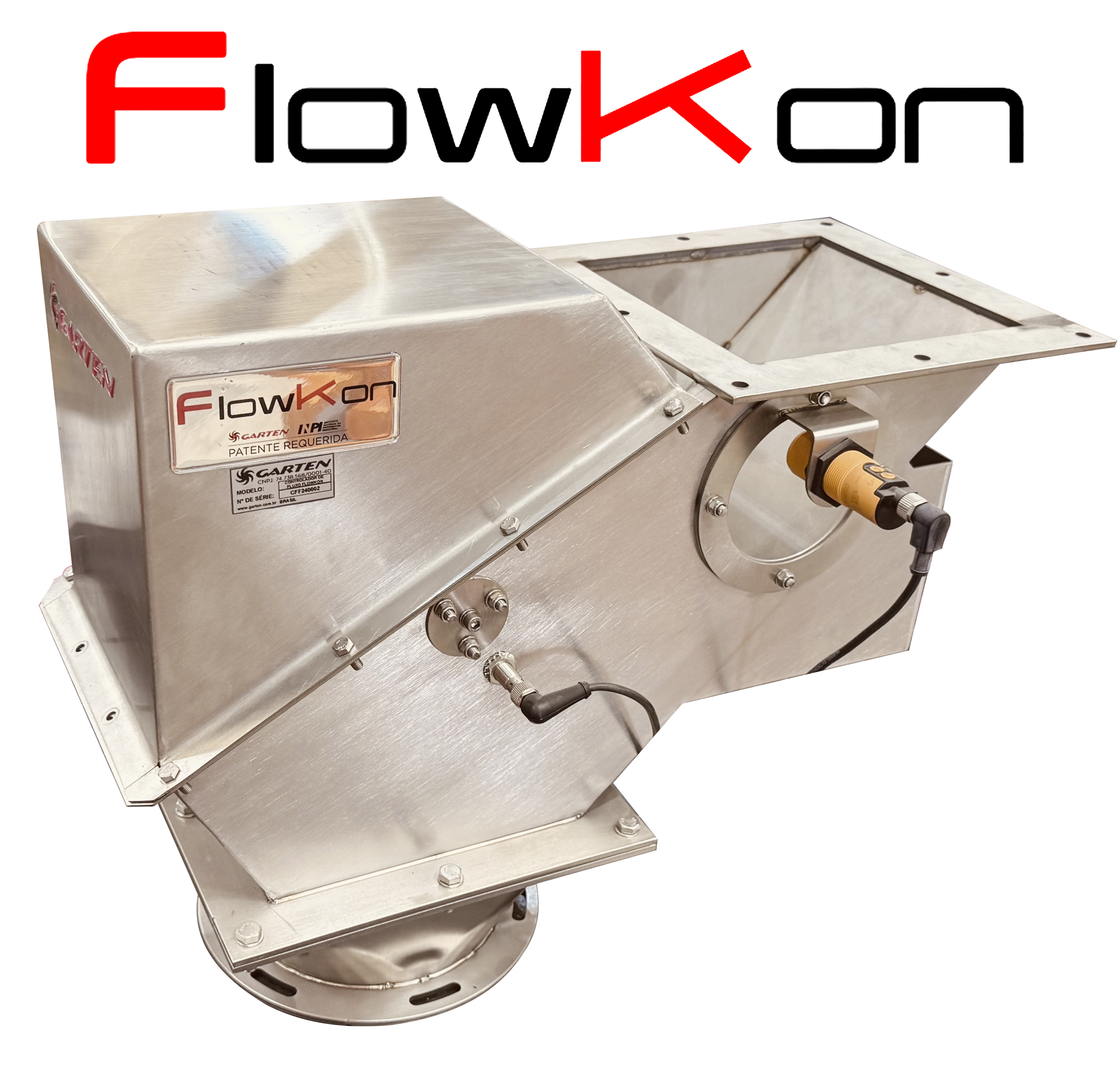

The FlowKon precisely controls the feeding of granular products, ensuring consistent dosing and stability in food production lines. Compact and easy to integrate, it optimizes flow, increases efficiency, and ensures process quality.

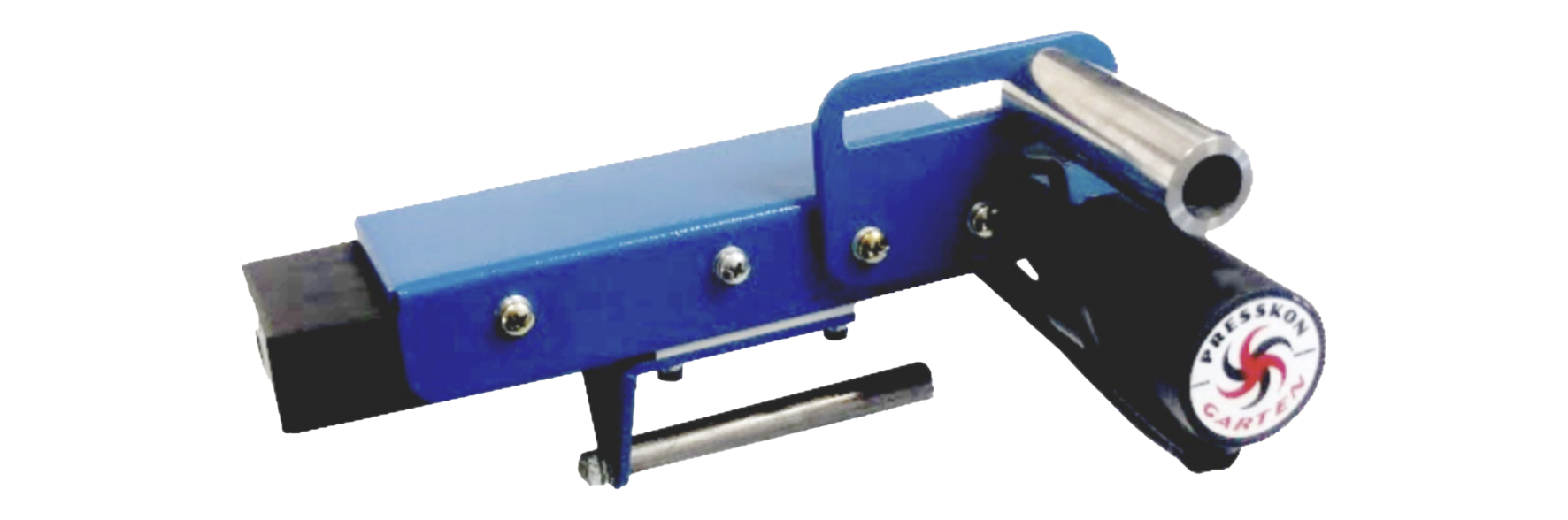

The PressKon automates pressure control in polishers and whiteners, adjusting the rice flow in real time to ensure consistent whitening and polishing. With motorized actuation and HMI supervision, it provides operational precision and full integration with the plant’s automation system.

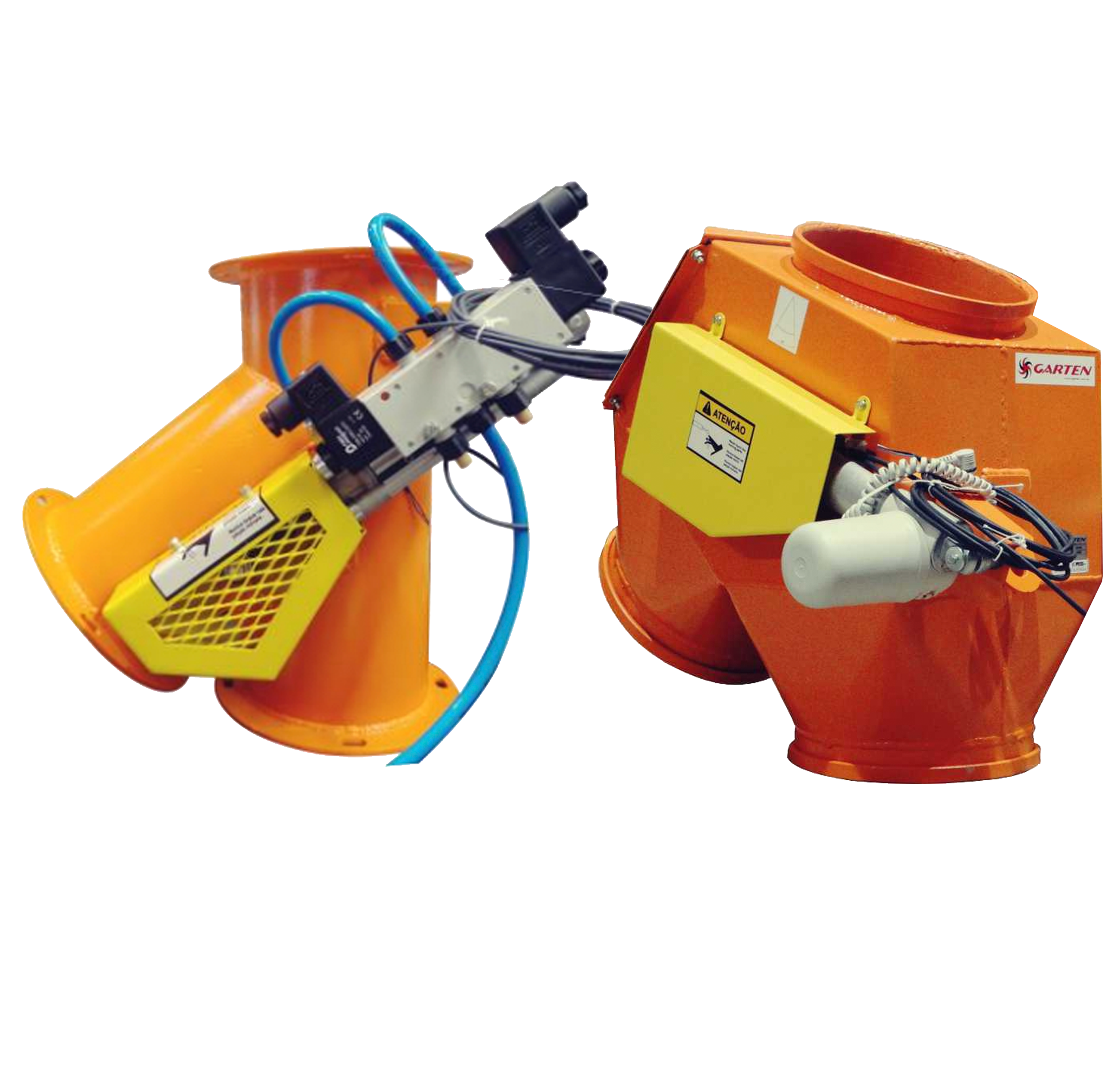

The Flow Diverter keeps grain processing in constant motion, redirecting the product with precision and eliminating buildup that could interrupt the line. With electric or pneumatic options, it ensures efficiency, stability, and full adaptation to the plant’s infrastructure.

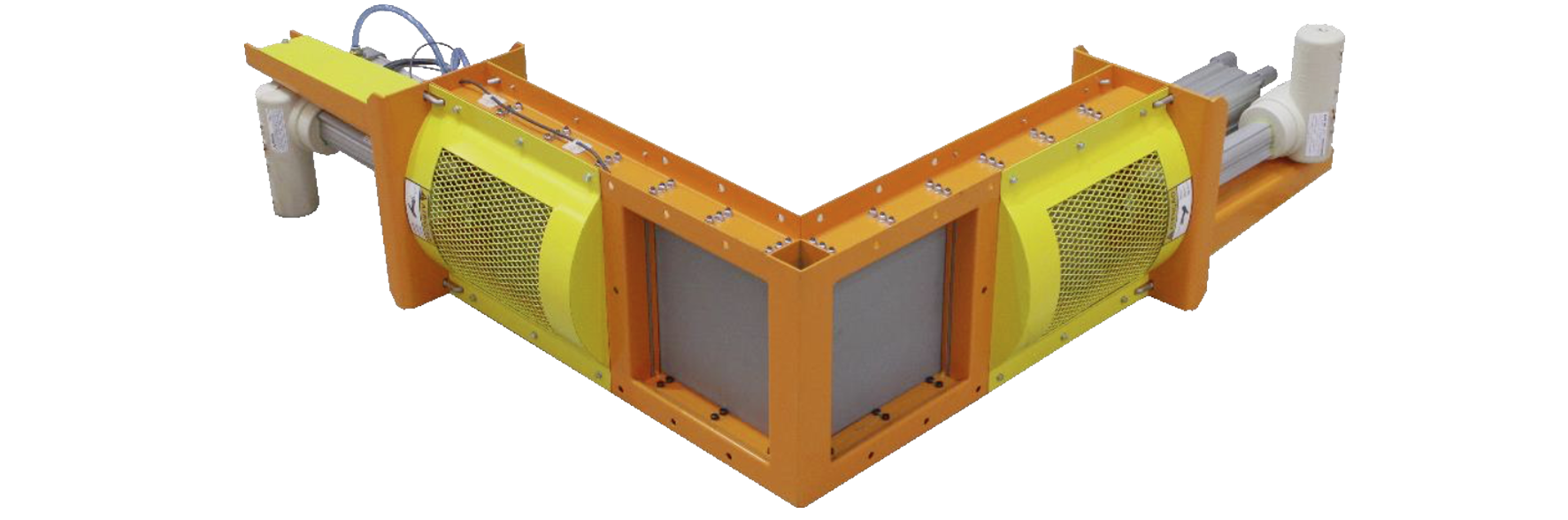

The Flow Divider ensures precise division and modulation of grain flow in special applications, maintaining continuous operation without buildup and with total stability. With pneumatic and electric actuation options, it provides fine control and direct integration with industrial automation.