InfoKlima provides precise and continuous environmental monitoring, measuring temperature, humidity, and rainfall. Compact, robust, and efficient, it ensures reliable readings in any environment and direct integration with automation systems.

The Diff Press Differential Pressure Meter monitors the pressure difference between two environments in real time and sends this data directly to the automation system, ensuring precise and immediate control.

The Med-Umi measures grain moisture directly in the dryer flow, delivering laboratory-level precision in real time, with efficient and fully controlled operation. With cutting-edge technology and full integration, it ensures superior quality and eliminates uncertainties in the process.

The MedFlow measures the flow of granular products with high precision and controls the amount entering the process, ensuring stable feeding and fine adjustments in the machines. With simple and fast installation, it optimizes production, reduces losses, and brings real control to the line.

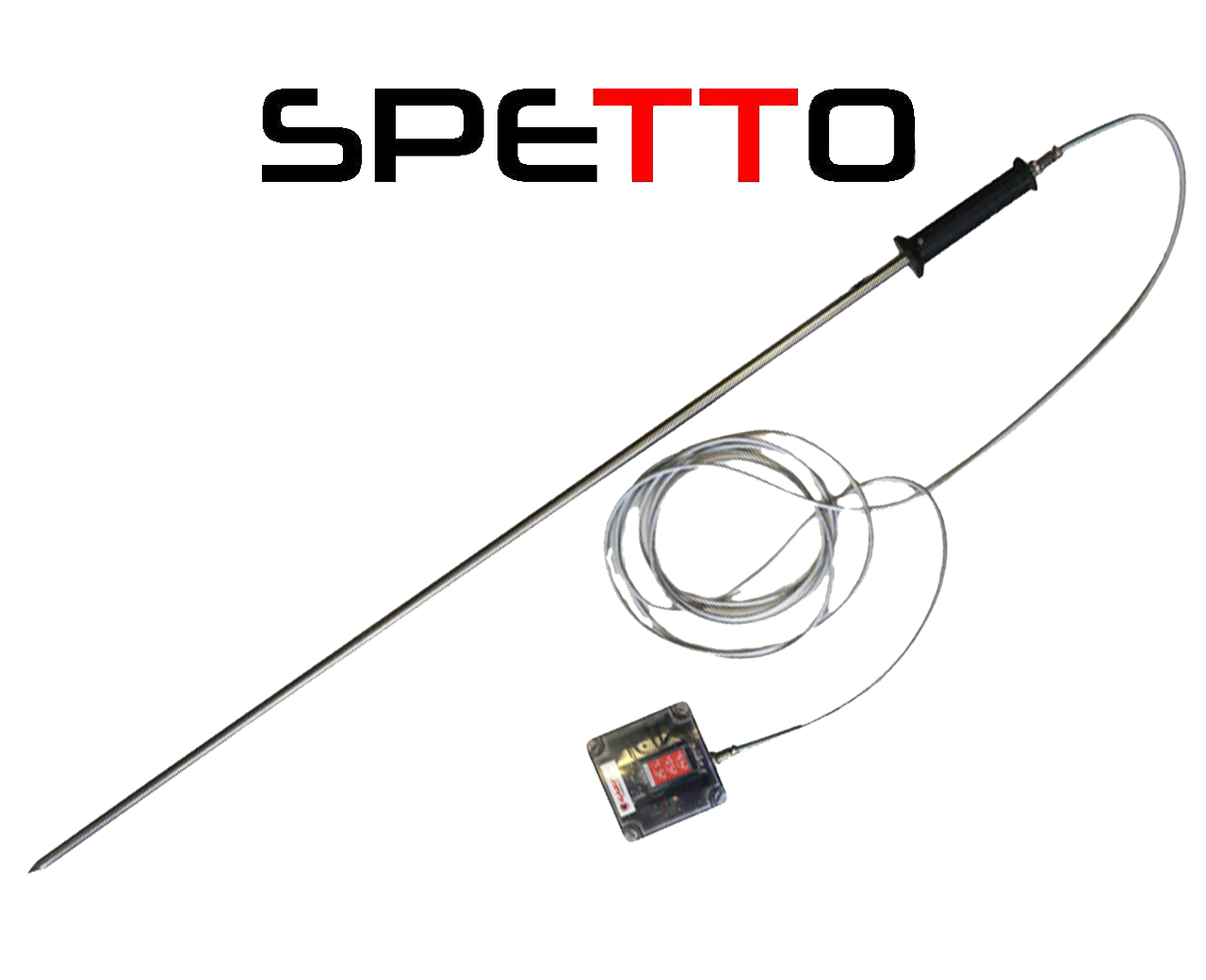

The Spetto accurately measures temperature at depth in germination tanks, revealing the true thermal condition across all grain layers. Portable and simple to use, it ensures reliable control of the malting process and quick decisions based on real data.

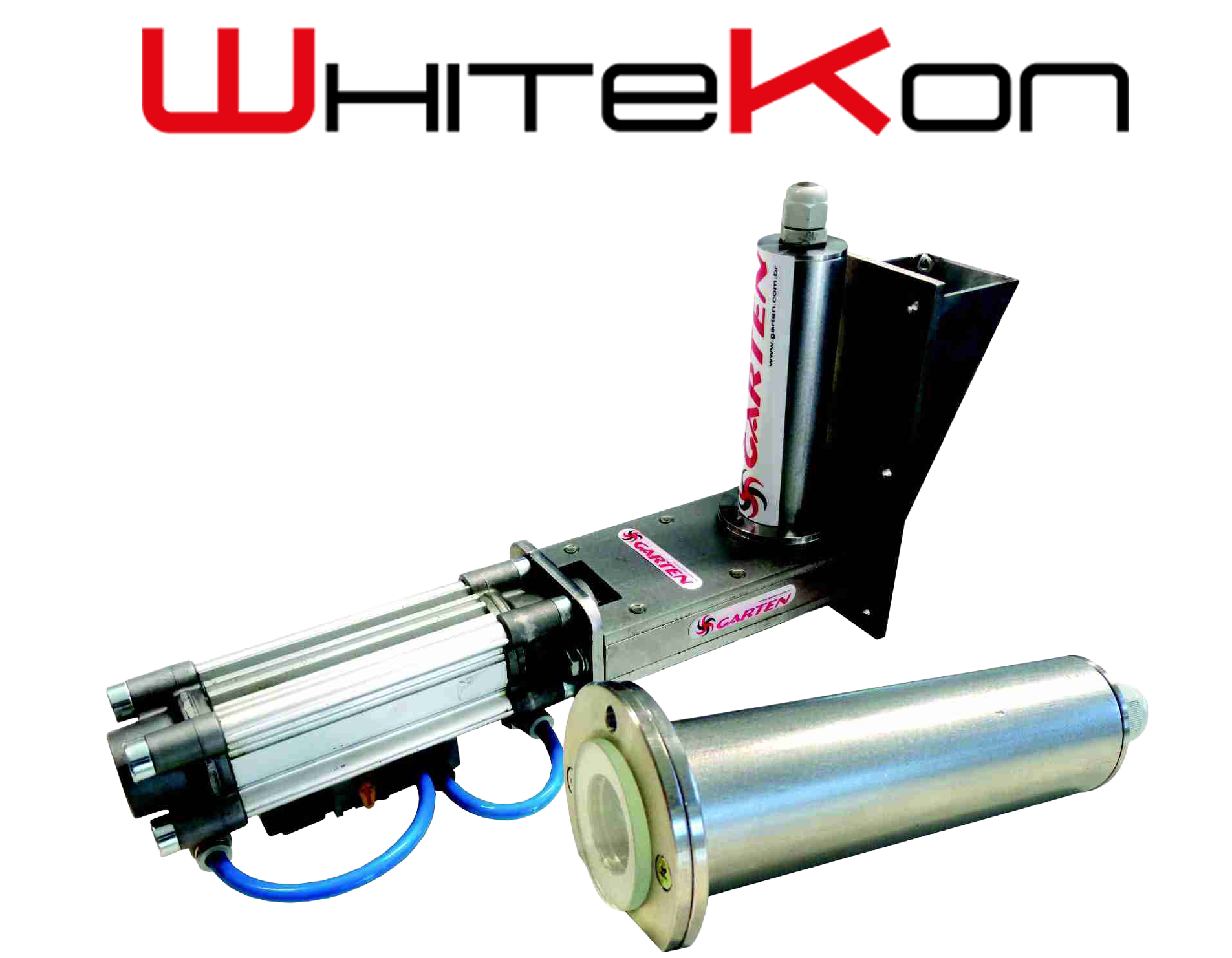

The WhiteKon measures whiteness levels directly at the outlet of polishers and whiteners, ensuring precision and automatic machine adjustment in real time. With an RGB sensor and microprocessed control, it delivers consistent results and full integration with industrial systems.

The WhitePRO is a portable whiteness meter, allowing practical use at any point in the plant, with precise measurements, simple operation, and autonomy that supports continuous process control.

The GasMeter detects, with extreme advance notice, any abnormal increase in the cellular respiration of grains in the silo, alerting even weeks before a temperature rise occurs. With full integration into the STARK system, it ensures improved preservation and reduces storage losses.

The Sheriff monitors critical conveyor points in real time, identifying failures before they become stoppages, accidents, or equipment damage. With strategic sensors and industrial communication, it provides continuous and reliable protection for the entire line.

The TempKon monitors, in real time, the temperature of the grain mass at the outlet of polishers and whiteners, ensuring precise thermal control at critical processing points.

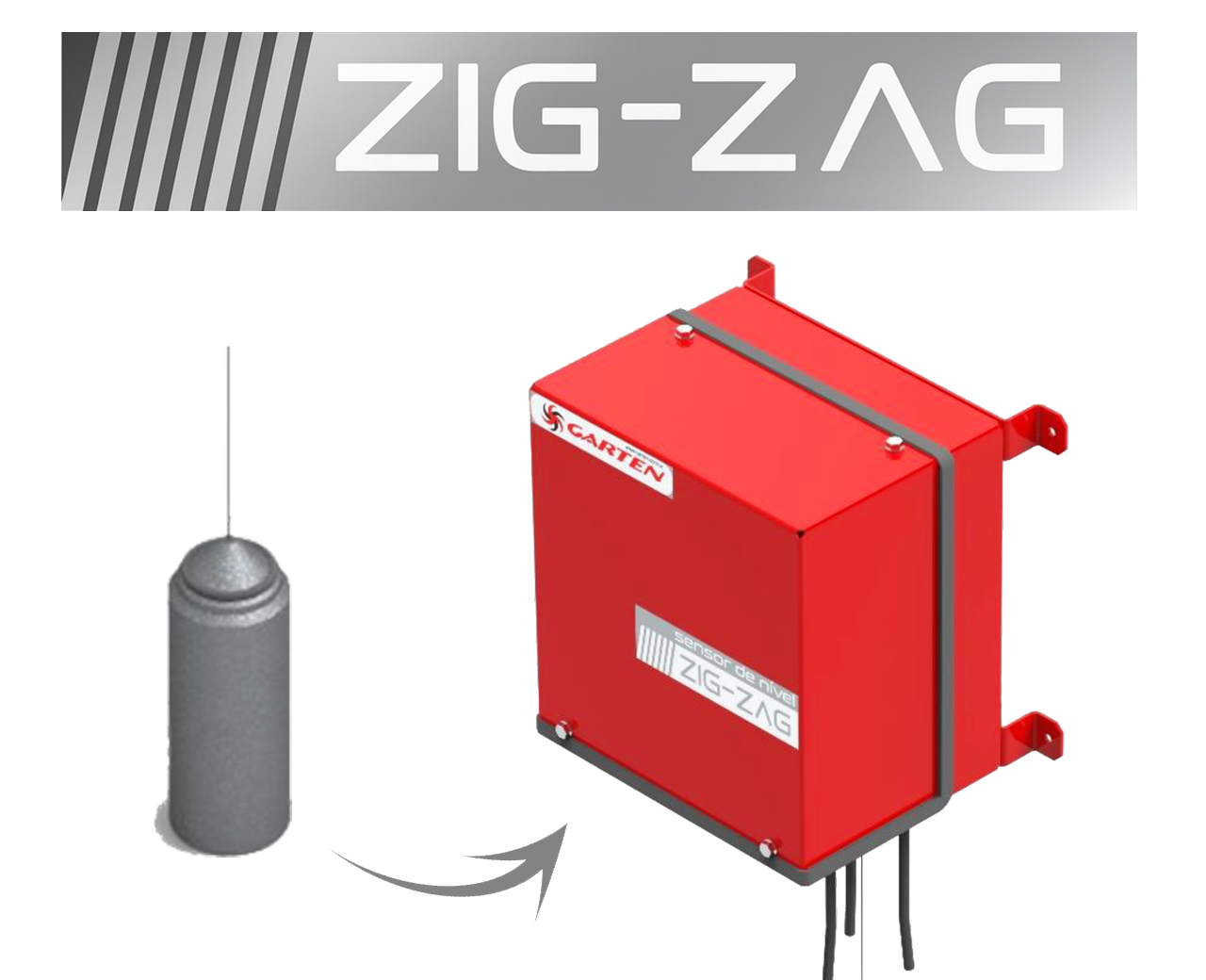

The ZIG-ZAG accurately measures product height in silos and bins, supplying the automation system with the approximate stored volume. With a programmable pendulum and armored construction, it ensures reliable readings even in dusty environments.